X-Ray CT Inspection: Non-Destructive Internal Defect Detection Solutions for Plug-in Units, Nozzles, Connectors, and Manifolds

- Pubdate 2026-02-06

X-Ray CT Inspection: The Ultimate Solution for Non-Destructive Internal Defect Detection in Precision Components

In modern industrial manufacturing, the quality of precision components such as plug-in units, nozzles, connectors, and manifolds directly determines the performance and reliability of the final product. X-Ray CT inspection

technology, with its unique non-destructive three-dimensional imaging capability, provides a revolutionary approach to uncovering potential product defects.

Why Choose X-Ray CT Inspection? Solving Your Core Challenges

Are your products facing internal voids, cracks, poor assembly, or foreign object inclusion that cannot be detected by visual inspection or traditional 2D X-Ray methods? These hidden issues not only affect product performance but may also lead to serious quality incidents. X-Ray CT inspection penetrates materials to obtain complete three-dimensional internal structural data in a non-destructive manner, leaving no hidden defects undetected.

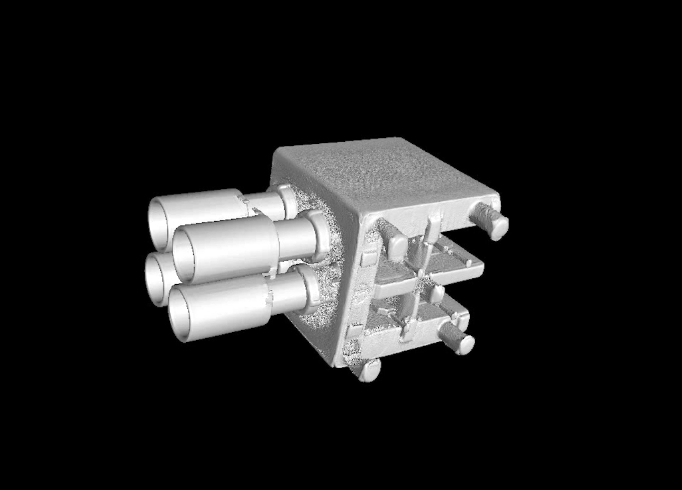

Plug-in Units: Ensuring Stable and Reliable Electrical Connections

Internal soldering quality, pin deformation, and molding defects in plug-in units directly affect electrical performance. High-precision CT scanning clearly reveals minute internal misalignments, ensuring that every connection is secure and reliable.

Fig. 1: X-Ray CT inspection reveals the fine internal structure and potential defects of a plug-in unit

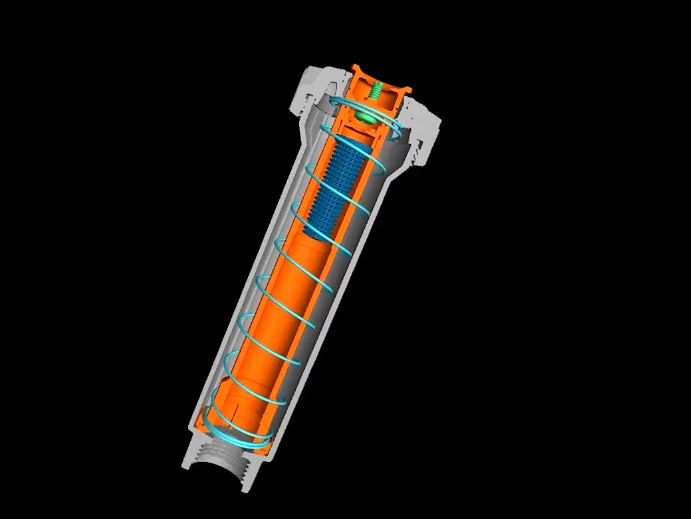

Nozzles: Optimizing Fluid Channels to Enhance Spray Performance

The internal flow channels of nozzles are small and complex, and any blockage or manufacturing deviation can affect spray accuracy. CT inspection precisely analyzes flow channel structures and verifies design consistency, making it an indispensable quality assurance tool for high-end nozzle manufacturing.

Fig. 2: X-Ray CT inspection clearly visualizes the internal fluid channel structure of a nozzle

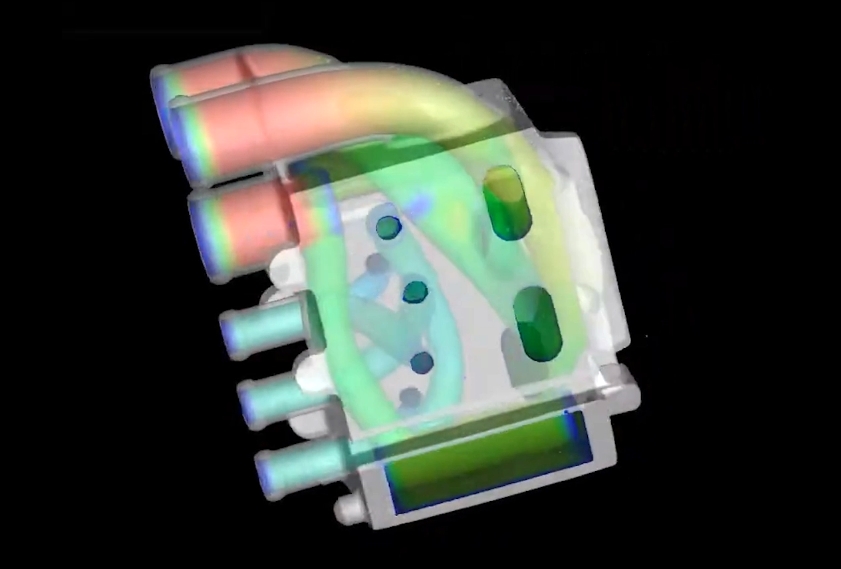

Connectors: Safeguarding Signal Transmission Integrity

Minor defects in connector pin alignment or solder joints can lead to signal attenuation. CT inspection provides a complete three-dimensional view, helping engineers accurately locate internal open-circuit or short-circuit risks.

Fig. 3: X-Ray CT inspection provides a 3D view of internal pins and solder joints within a connector

Manifolds: Precise Evaluation of Internal Flow Channels and Structural Integrity

As the core of a fluid system, the uniformity of wall thickness and the presence of casting porosity in manifolds are critical. X-Ray CT inspection builds accurate three-dimensional models, enabling non-destructive full-scale measurement and defect evaluation.

Fig. 4: X-Ray CT inspection displays complex internal flow channel structures and potential defects within a manifold

Choose Wahfei X-Ray CT to Enhance Your Product Competitiveness

Wahfei X-Ray CT inspection equipment supports comprehensive improvement from R&D optimization to production quality control, safeguarding your precision manufacturing.

Contact Us Now to Obtain a Customized Inspection Solution