How Open-Tube Microfocus X-Ray Inspection Technology Empowers Precision Electronics and Semiconductor Manufacturing

- Pubdate 2026-01-30

Breaking the Limits: Open-Tube Microfocus X-Ray Applications and Original Inspection Images

As electronic products continue to miniaturize and integration levels rise, especially in key fields such as semiconductor packaging and advanced electronic components, even the smallest defect can lead to functional failure. The advantages of open-tube microfocus X-Ray, and how it helps safeguard product quality and improve production yield, will be presented below.

Technological Innovation: How Open-Tube Microfocus X-Ray Overcomes Traditional Limitations

In the past, closed-tube X-ray sources were widely used due to their maintenance-free convenience. However, as semiconductor components continue to shrink, the demand for image granularity has increased significantly. With focal spot sizes at the micrometer level, closed-tube sources are gradually reaching their technical limits. In applications requiring the inspection of tiny solder joints, fine cracks, or sub-micron-level defects, image blur and limited magnification directly affect inspection accuracy and reliability.

Open-tube microfocus X-Ray, as a core component of precision X-ray inspection systems, effectively addresses these challenges. Its technical advantages include:

Ultra-high precision: Achieves focal spot sizes below 1 μm (and even approaching the nanometer level), far exceeding closed-tube sources and ensuring clear imaging of micro-scale defects.

High optical magnification: A larger X-ray cone angle and higher optical magnification allow tiny structures to be clearly enlarged on screen, meeting high-precision inspection requirements.

High reliability: Capable of operating at higher tube voltages, delivering stronger penetration performance suitable for inspecting thicker or higher-density samples.

Serviceability: The open-tube design allows users to replace consumables such as filaments, effectively reducing long-term operating costs.

Professional Application Areas of Open-Tube Microfocus X-Ray Inspection Systems

1. Precision Electronic Components and Automotive Electronics

From compact wearable devices to automotive electronics with extremely high reliability requirements (such as ADAS modules and battery pack solder joints), non-destructive inspection of internal defects in BGA, CSP, QFN, and other packages is essential to ensure long-term stable operation.

2. Advanced Semiconductor Packaging and Inspection

In semiconductor packaging and testing, open-tube microfocus X-Ray is an essential tool for solder void ratio analysis, wire sweep detection, die delamination inspection, and internal structure examination of 3D packages such as SiP and PoP, directly impacting chip performance and service life.

3. Aerospace and Defense-Grade Reliability Assurance

For aerospace and defense applications involving main control boards and high-reliability components, quality standards demand zero defects. Open-tube microfocus X-Ray provides the most detailed internal structural analysis, delivering the highest level of reliability assurance for equipment operating in extreme environments.

Original Inspection Images: Micron-Level Defects Revealed with Clarity

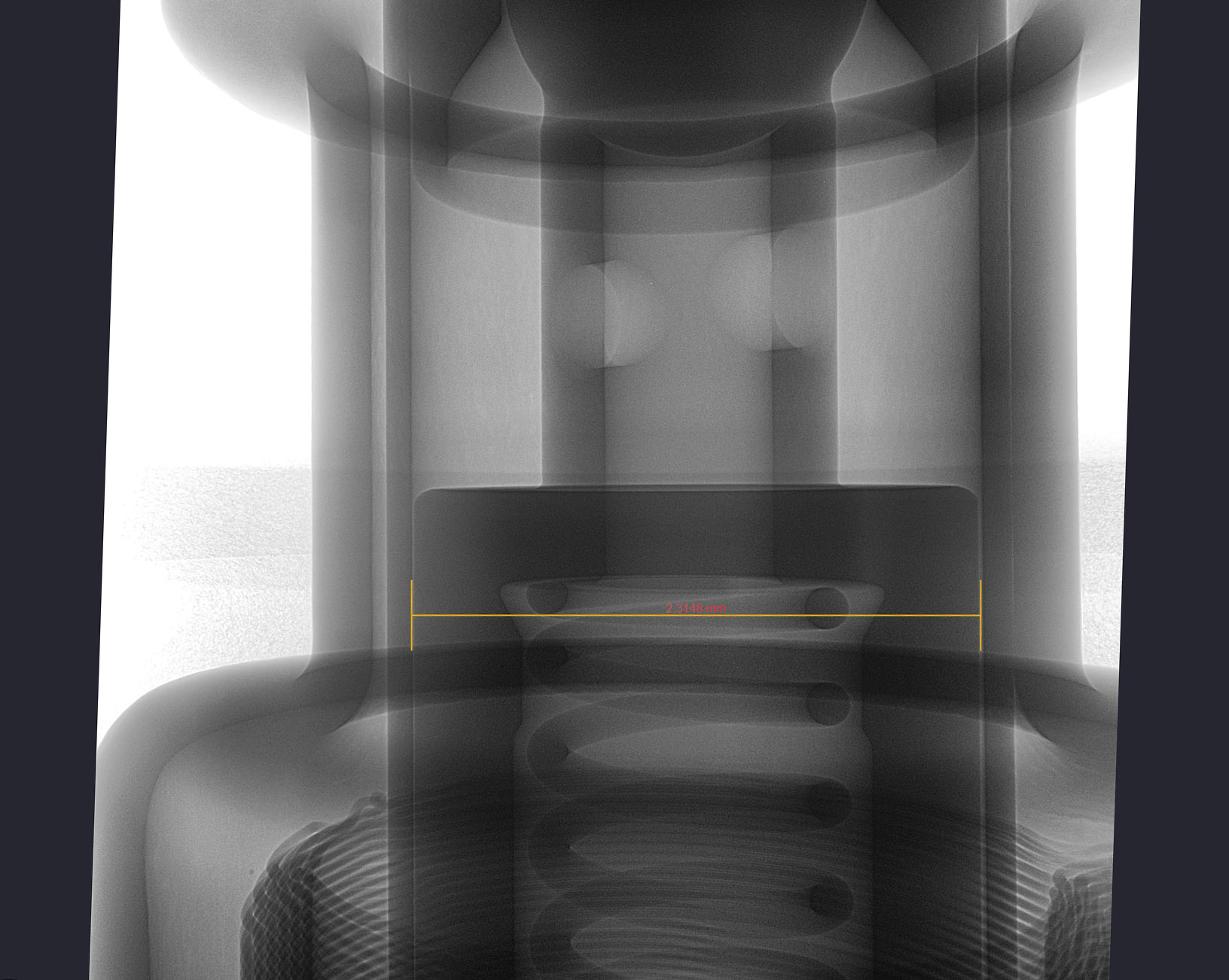

Fig. 1: High-resolution X-Ray view of internal structures in precision components

Fig. 2: Non-destructive inspection of internal interconnections in electronic components

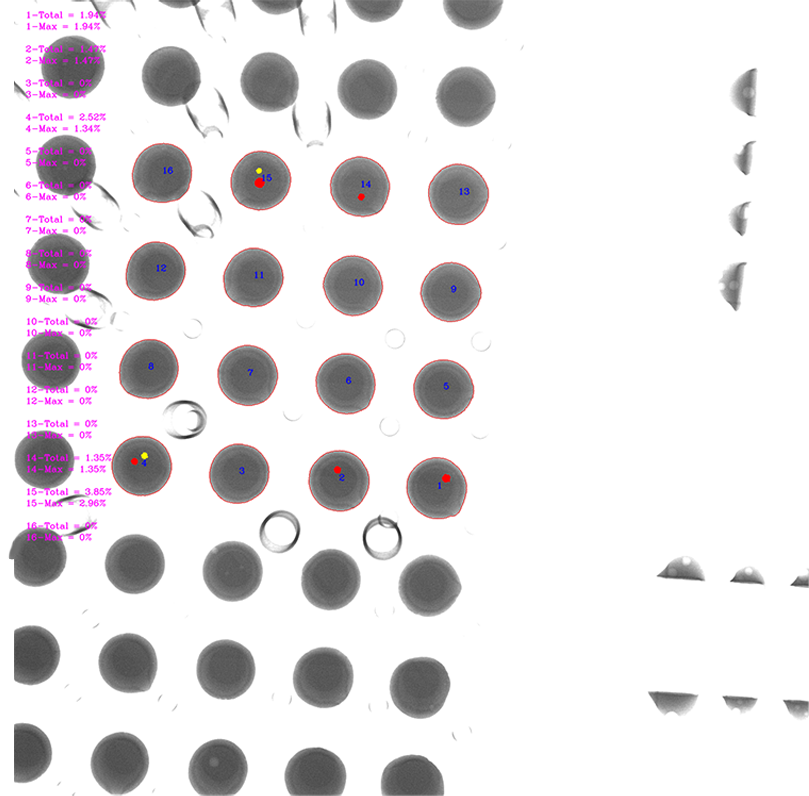

Fig. 3: Precise solder joint void ratio analysis to ensure connection reliability

Choose Professionalism, Choose the Future

In an era of industrial manufacturing that demands extreme precision, choosing open-tube microfocus X-Ray inspection systems means choosing the highest quality standards and the most reliable production assurance.

Learn More About the S160 Offline X-Ray Inspection System