About us

About us

Shenzhen Wahfei Technology Co.,Ltd.

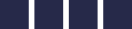

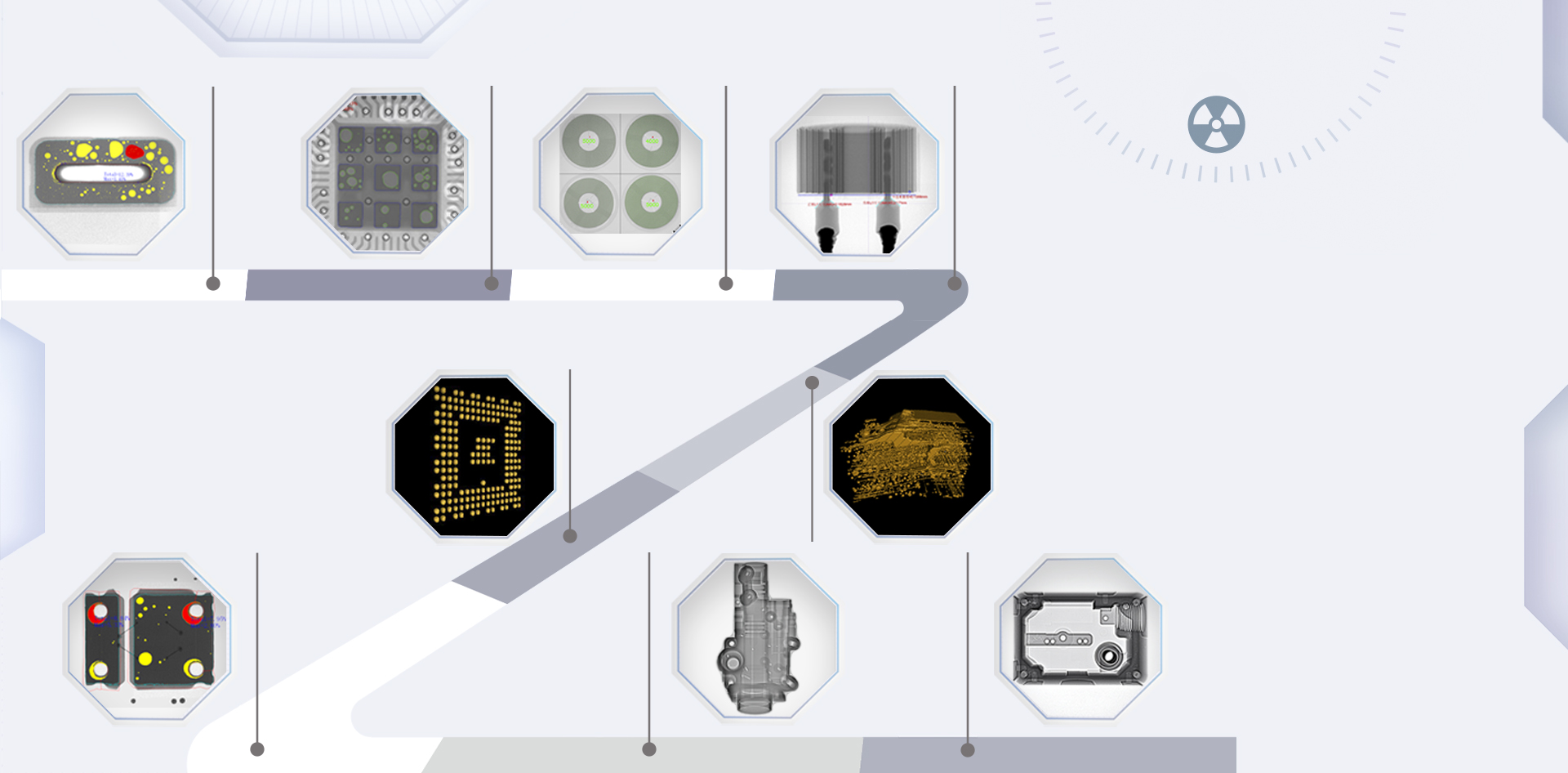

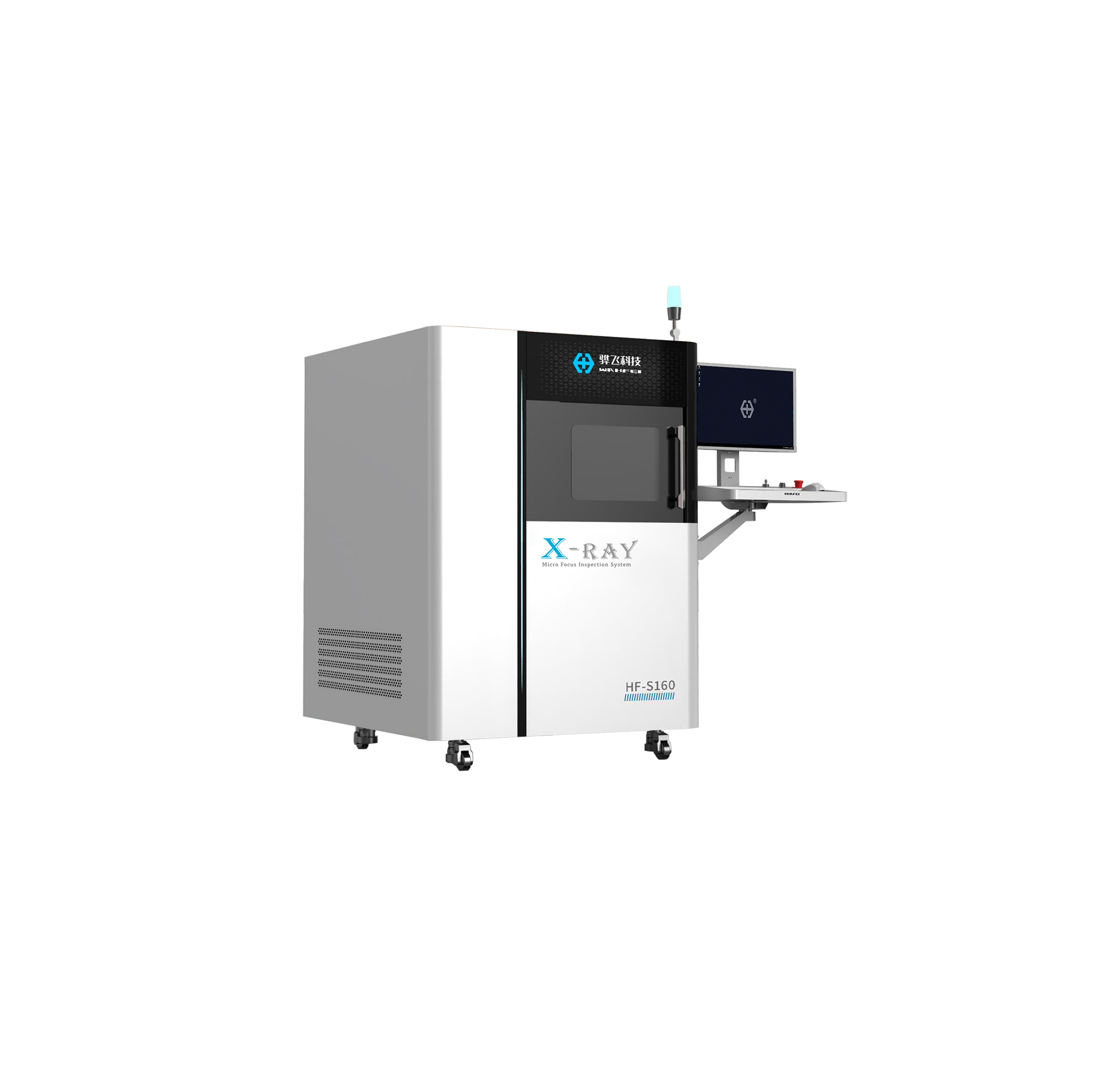

Shenzhen Wahfei Technology Co.,Ltd.,established in 2018,is a high-tech enterprise specializing in industrial X-Ray intelligent inspection technology.The company is dedicated to providing high-precision and high-efficiency non-destructive testing(NDT)solutions for the manufacturing industry.Building on X-Ray imaging inspection and driven by advanced image processing and AI applications,Wahfei has developed a comprehensive full-stack intelligent inspection system that integrates hardware,software,and data.

Read more

News

2026-03-06

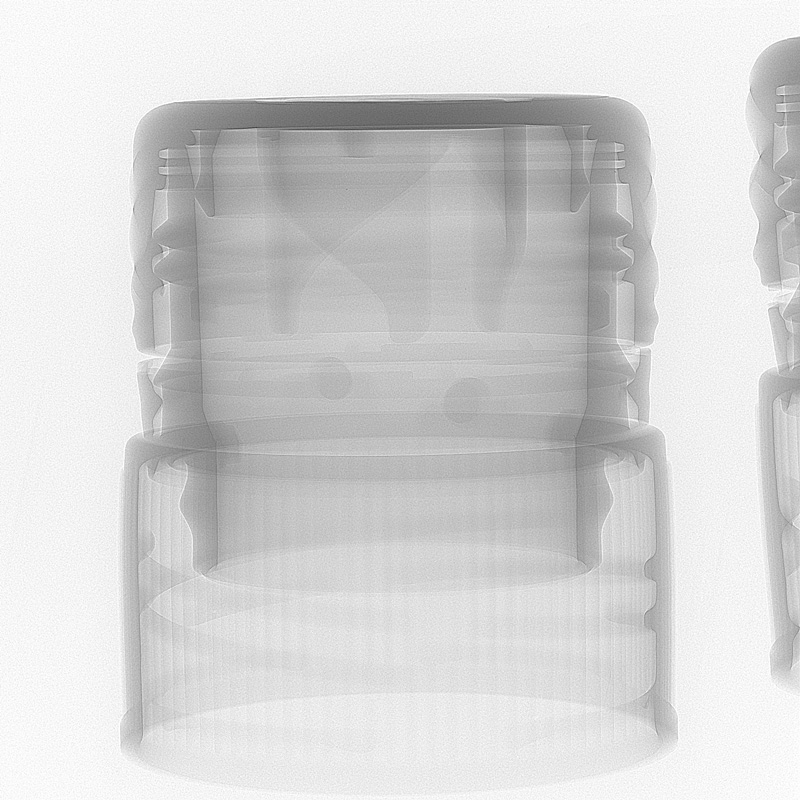

An electronic atomization device manufacturer introduces X-ray inspection systems for e-cigarette testing.

How a leading manufacturer uses advanced X-ray inspection for non-destructive precision testing of internal structures, solving core quality challenges such as e-liquid leakage and component misalignment to enhance product reliability and user experience. Discover the critical value of X-ray technology in e-cigarette production.

2026-02-04

Leoni Electrical acquires X-ray inspection equipment for cable harnesses

In the manufacturing process of high-density cable harnesses, the true determinants of reliability are often not apparent at the visual level. Conductor displacement, inadequate terminal crimping, hidden internal breaks, or foreign object contamination—should such issues reach downstream assembly stages, they invariably lead to system-level rework or even batch-level risks. Relying solely on spot checks or electrical performance testing proves inadequate for comprehensively addressing these structural hazards. It is precisely within this manufacturing context that the value of X-ray inspection equipment becomes evident.

2026-02-03

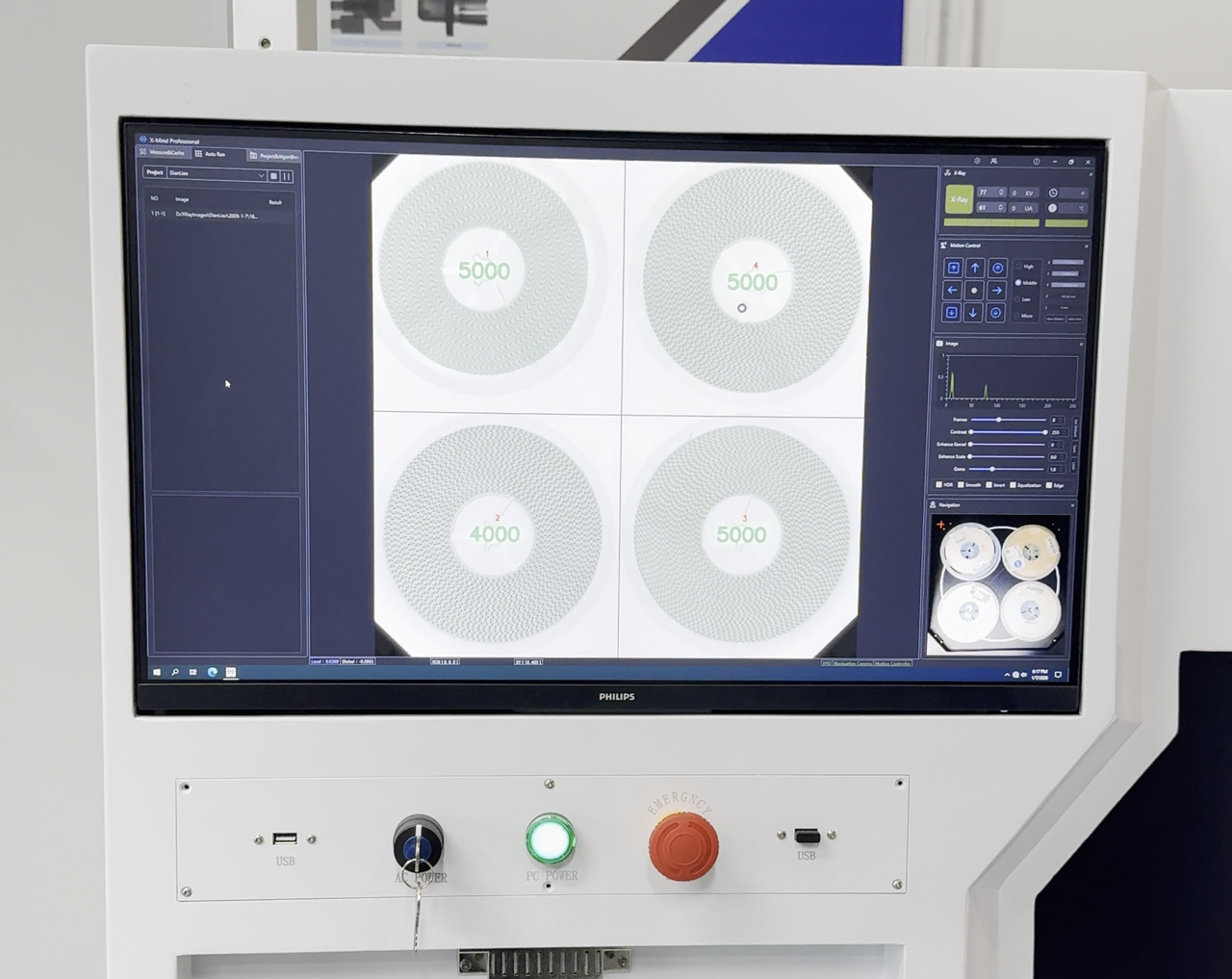

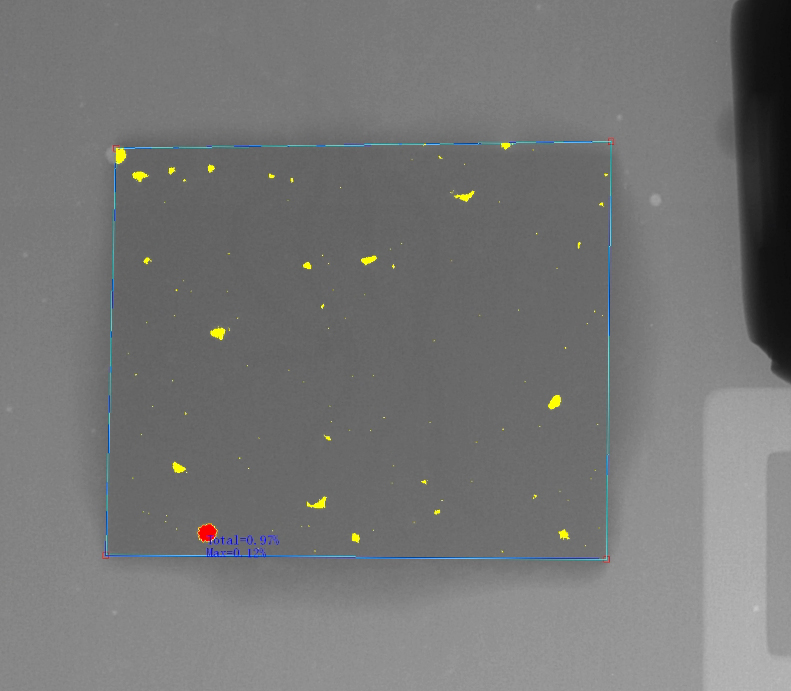

Introducing the X-Ray Component Counting and Inspection System: Empowering the Electronic Components Supply Chain

How a Shenzhen Technology Company Significantly Enhanced Electronic Component Inventory Management and Quality Inspection Efficiency by Acquiring Huafei's Advanced X-Ray Component Counting and Inspection System, Delivering More Reliable Product Services to High-Precision Fields Such as Military and Aerospace.

2026-03-05

X-Ray Inspection Machine: High-Precision Fully Automatic Batch Inspection and Comprehensive Radiation Protection

Product quality is directly related to a company's market reputation and profit margins. With the continuous upgrading of product reliability requirements in consumer electronics, industrial control, medical equipment, and other fields, traditional inspection and simple electrical testing can no longer meet the demands. Many factory purchasing managers and business owners are looking for a solution that can both improve inspection accuracy and reduce operating costs. As an industry-recognized high-end inspection equipment, the X-Ray Inspection Machine is gradually becoming the new standard for quality control.

2026-02-28

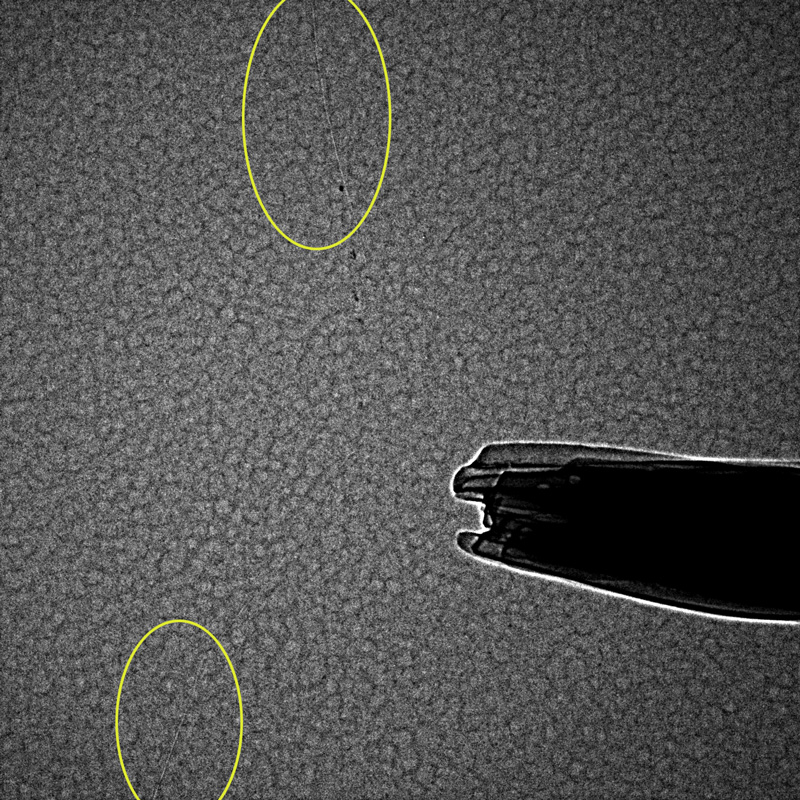

X-ray non-destructive testing of ceramic plates for micro-cracks, leaving no hidden fractures undetected.

X-ray inspection technology, with its unique penetrating capability, stands as the ideal choice for non-destructive testing of microcracks in electronic ceramic substrates. It can penetrate dense ceramic materials, revealing internal structural defects as high-resolution images, thereby exposing concealed microcracks. This serves not only as a quality control measure but also as a critical safeguard ensuring product stability under extreme operating conditions.

2026-02-07

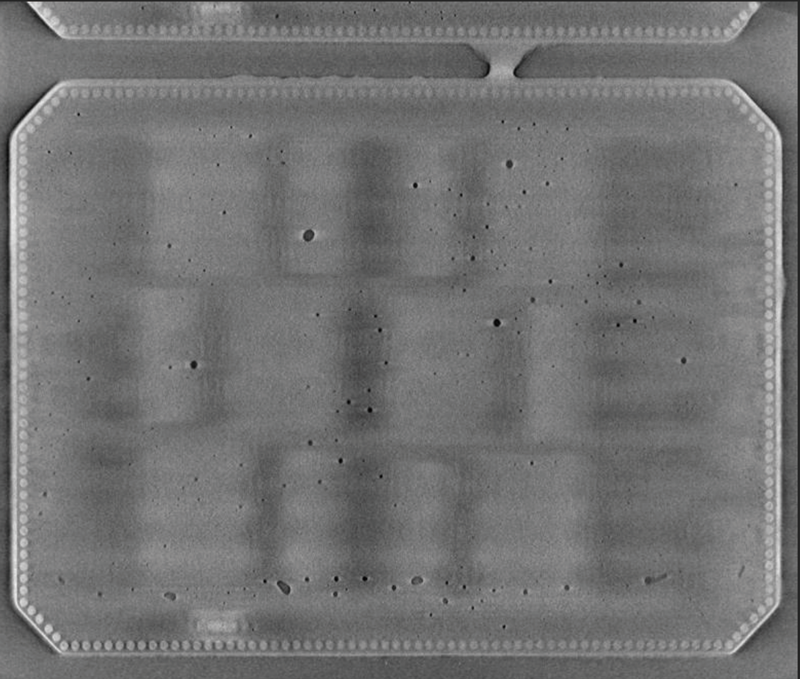

3D-CT AXI Enables Non-Destructive Testing of IGBT Power Modules

Reliability is paramount for IGBT (Insulated Gate Bipolar Transistor) power modules in the semiconductor field. Defects such as voids within the welded layer pose critical risks to performance and lifespan. To address this challenge, Huafei has introduced a 3D-CT AXI inspection system specifically engineered for IGBT power modules. This equipment achieves industry-leading inspection speeds while reliably detecting manufacturing defects that are difficult to identify using conventional methods. It also offers outstanding operational convenience and maintainability.

2026-01-30

How Open-Tube Microfocus X-Ray Inspection Technology Empowers Precision Electronics and Semiconductor Manufacturing

The open-tube microfocus X-ray, serving as the core component of precision X-ray inspection equipment, resolves this critical challenge. Its technical advantages are manifested in: ultra-high precision, high optical magnification, and high reliability. Maintainability: the open-tube design permits users to replace consumables such as filaments themselves, effectively reducing long-term operational costs. Open-tube microfocus X-ray technology, as the core component of precision X-ray inspection equipment, resolves this critical challenge. Its technical advantages are manifested in: ultra-high precision, high optical magnification, exceptional reliability, and maintainability. The open-tube design permits users to replace consumables such as filaments themselves, effectively reducing long-term operational costs.

2026-01-24

X-Ray Inspection of Corrugated Hose Welds

As a critical flexible connector in industrial piping systems, the weld quality of bellows directly impacts the safety and reliability of the entire system. This paper will delve into how X-ray non-destructive testing technology can be utilized to accurately identify potential defects in the longitudinal welds and end joint connections of bellows.

2026-01-23

X-Ray Component Counting & Inspection Combo Machine — Official Operation Guide

In electronic manufacturing, SMT incoming inspection, and semiconductor packaging processes, X-Ray inspection equipment does more than simply “see inside structures.” It directly affects material counting accuracy, inspection efficiency, and the stability of downstream processes. To address the issues of low efficiency, high error rates, and the inability of traditional manual counting to simultaneously detect internal defects, integrated X-Ray solutions that combine material counting and inspection are increasingly becoming standard equipment for many enterprises.

2026-01-15

X-Ray Automated Inspection for Internal Product Defects - Solving Inspection Challenges for BGAs, IGBTs

Simple operation allows even non-technical users to get started quickly. One-click detection identifies internal defects such as BGA solder joint failures, IGBT bubbles, and PCB solder bridges. Boost inspection efficiency with MES system integration to reduce scrap rates and labor costs.

2025-12-19

X-Ray Inspection for High-End Cosmetics like Lipsticks and Liquid Lip Tints & Plastic Packaging

Traditional inspection methods often rely on manual sampling or destructive unpacking. This is not only inefficient but also fails to cover every product leaving the factory. Especially for items with composite plastic and metal packaging, such as lipsticks and liquid lip tints, how to inspect the internal condition without opening, touching, or damaging the exterior has become an industry pain point. This is exactly where modern industrial X-ray inspection equipment comes into play. Leveraging the strong penetrative power and density resolution of X-rays, we can conduct a thorough “CT scan” of each product, examining it from the inside out.

2025-11-17

Core Considerations for Procuring X-Ray Inspection Equipment

In the fields of electronics manufacturing, integrated circuit packaging, automotive parts, and precision casting inspection, X-Ray equipment has become a critical tool for quality control. However, many companies focus excessively on hardware parameters when purchasing equipment, while overlooking a core fact: under the same shooting conditions, image processing technology is the key factor that determines inspection results.

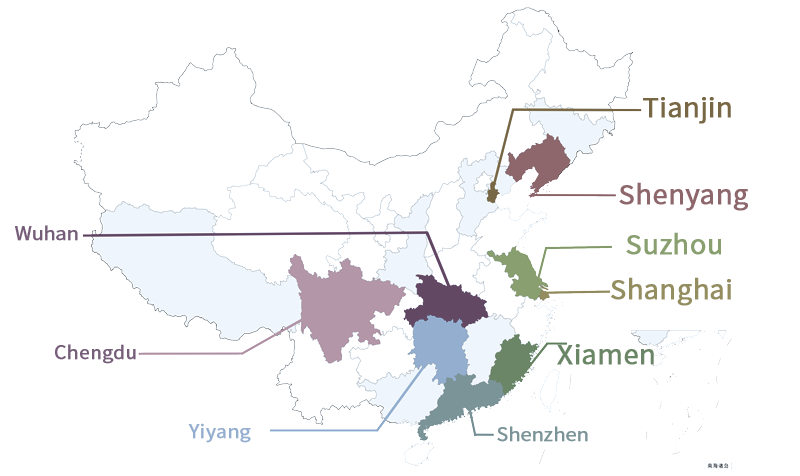

Our Offices

-

SuzhouEast China

SuzhouEast China -

DalianNortheast China

DalianNortheast China -

YiyangCentral China

YiyangCentral China -

TianjinNorth China

TianjinNorth China -

ShanghaiEast China

ShanghaiEast China -

XiamenEast China

XiamenEast China -

ShenzhenSouth China

ShenzhenSouth China -

WuhanCentral China

WuhanCentral China -

ChengduSouthwest China

ChengduSouthwest China