X-Ray Non-Destructive Testing for FPC Circuits

- Pubdate 2025-12-02

X-Ray Non-Destructive Testing for FPC Circuits: Inspecting Hidden Defects in Flexible Circuit Boards

In modern electronics manufacturing, FPC circuits (Flexible Printed Circuits) have become indispensable core components. These highly flexible printed circuit boards, with their lightweight, bendable, and foldable characteristics, are widely used in smartphones, tablets, automotive electronics, medical devices, industrial control systems, and smart home equipment. However, the miniature size and complex structure of FPC circuits also pose significant challenges for quality inspection, as traditional visual inspection and electrical testing often fail to detect defects hidden inside.

Why Choose X-Ray Testing for FPC Circuits?

X-ray inspection technology provides a revolutionary solution for FPC circuit quality control. Unlike surface inspection methods, X-Ray can penetrate the multi-layer structure of FPC circuit boards and directly reveal the true condition of internal conductors. This non-destructive testing method causes no damage to samples while completing comprehensive scanning in just a few seconds, significantly improving inspection efficiency.

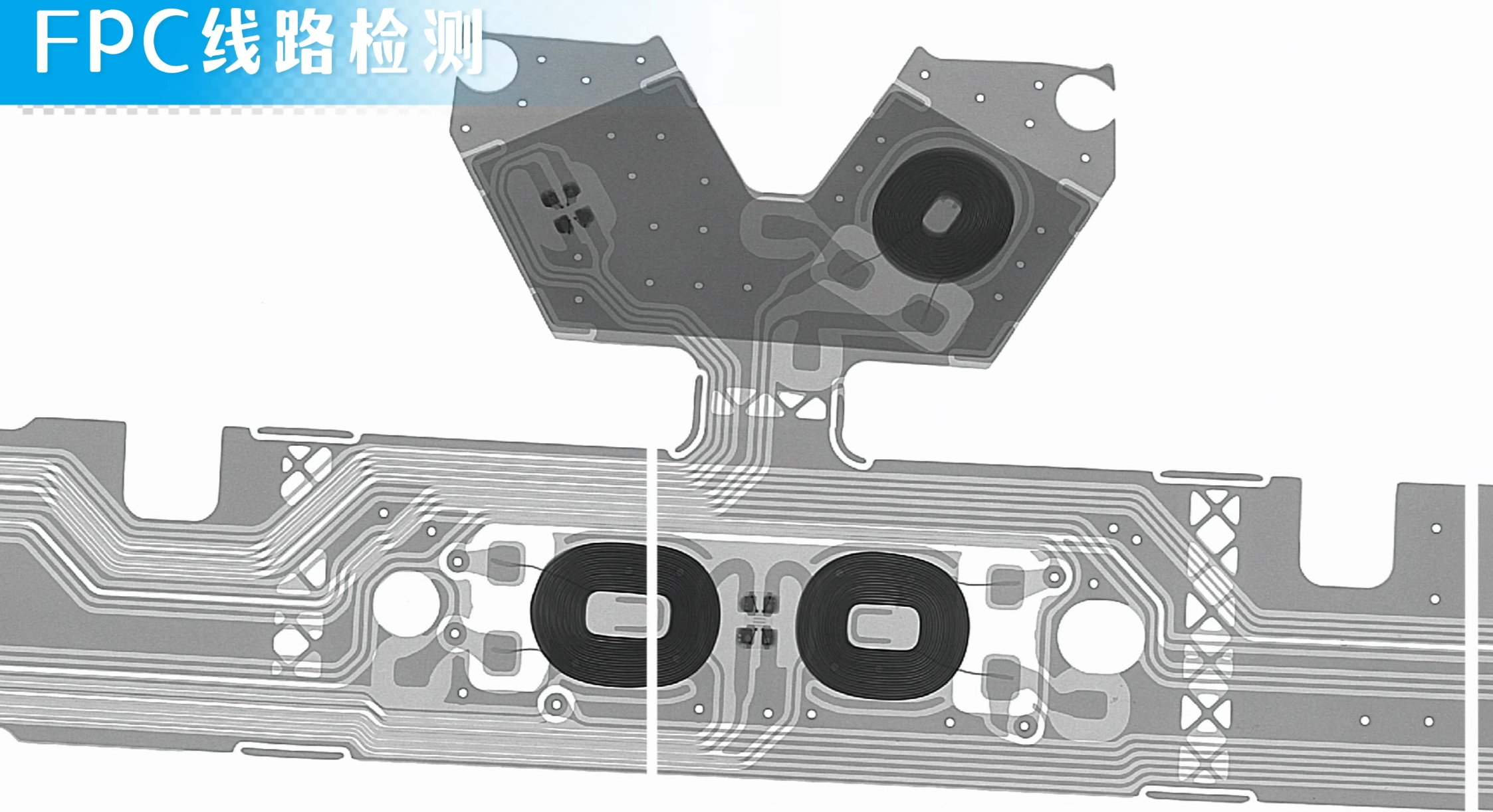

Through X-ray imaging, inspectors can clearly observe the conductor routing, soldering quality, layer-to-layer alignment, and potential minor defects in FPC circuits. Particularly for multi-layer FPC boards, X-Ray inspection can see through the structure of each layer, discovering issues that cannot be identified by the naked eye or conventional instruments, such as internal open circuits, trace misalignment, uneven copper foil thickness, and other hidden problems.

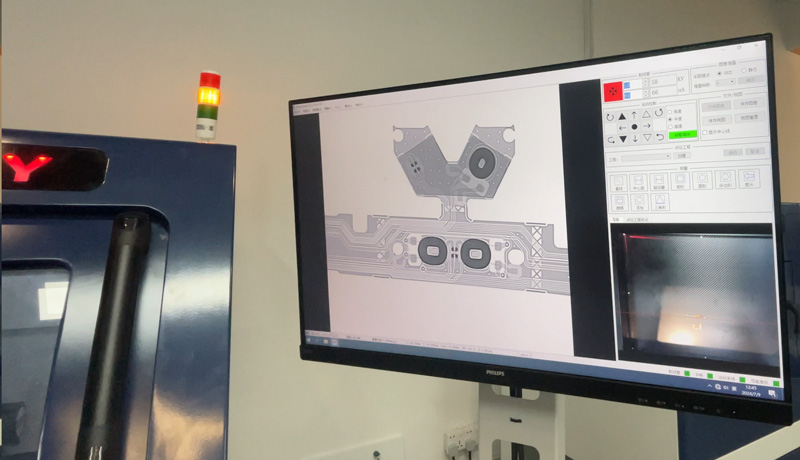

X-Ray Testing System Real-Time Imaging Interface

X-Ray Detection of Common FPC Circuit Defects

1. Short Circuit Issues

Circuit short circuits are one of the most common and harmful defects in FPC production. In X-ray images, short circuit points typically appear as abnormal connections between two originally separated conductors. This may be caused by copper foil residue, lamination offset, or insulation layer damage during the production process. Through X-Ray inspection, short circuit locations can be accurately identified before product shipment, preventing batch quality incidents.

2. Trace Spacing Anomalies

As electronic products move toward miniaturization, FPC circuit spacing requirements become increasingly stringent, with some high-density circuit boards having conductor spacing of only tens of microns. X-ray inspection can accurately measure trace spacing and identify areas that do not meet design specifications. Insufficient spacing may lead to degraded electrical performance or potential short circuit risks, while excessive spacing may affect the product's overall layout and functional implementation.

3. Open Circuits and Micro-Cracks

During bending or lamination processes, FPC conductors may develop imperceptible micro-cracks or complete breaks. These types of defects are nearly impossible to detect through visual inspection but can severely affect product reliability. X-Ray inspection can identify conductor continuity issues through grayscale differences, detecting even cracks just a few microns wide, providing strong assurance for product quality control.

High-Resolution X-Ray Imaging Clearly Reveals FPC Internal Structure

Core Advantages of X-Ray Inspection Technology

Non-Destructive Testing

No need to disassemble or damage samples; products can still be used normally after inspection, suitable for both sampling and 100% inspection scenarios

High-Efficiency Testing

Single scan takes only seconds, enabling in-line inspection to meet quality control needs for high-volume production

High-Precision Imaging

Micron-level resolution, capable of detecting minute defects and structural anomalies that traditional methods cannot find

Typical Application Scenarios

In consumer electronics, FPC connectors and camera module flex cables in smartphones and tablets require rigorous X-Ray inspection to ensure product reliability and service life. Automotive electronics have even more stringent quality requirements for FPCs, as circuit failures can lead to safety hazards, making X-Ray inspection an essential quality control step for automotive-grade FPCs.

FPC circuits in medical devices carry life monitoring and treatment functions, where any minor defect could have serious consequences. Through X-Ray inspection, potential issues can be thoroughly identified before products are put into use, ensuring stable operation of medical equipment. Although FPCs in industrial control systems and smart home devices operate in relatively mild environments, their long-term operational reliability requirements also need X-Ray inspection to guarantee.

Additionally, during the FPC development stage, X-Ray inspection can help engineers optimize design solutions and verify the feasibility of new processes. By comparing the internal structures of different production batches, directions for process improvement can be identified, enhancing product quality from the source.