PCBA X-Ray Inspection Video Demonstration

- Pubdate 2026-01-29

New Benchmark for PCBA Quality Control: How to Improve Factory Pass Rate with High-Precision X-Ray Inspection Equipment?

With the widespread application of bottom-terminated components such as BGA and QFN, traditional inspection methods can no longer meet high reliability requirements. Choosing a high-performance X-Ray inspection system is not only a guarantee of quality but also a manifestation of an enterprise's core competitiveness.

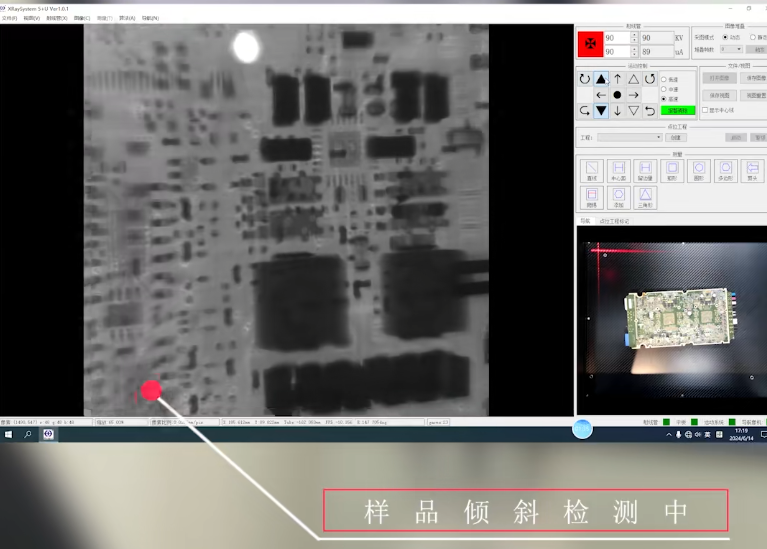

01Real-shot of Tilted Inspection Function

When inspecting high-density PCBA boards, vertical views often produce overlapping interference. Wahfei X-Ray equipment supports large-angle tilted inspection, enabling clear observation of solder ball wetting and internal bridging defects from the side.

Wahfei X-Ray System Multi-angle Tilted Inspection Demonstration

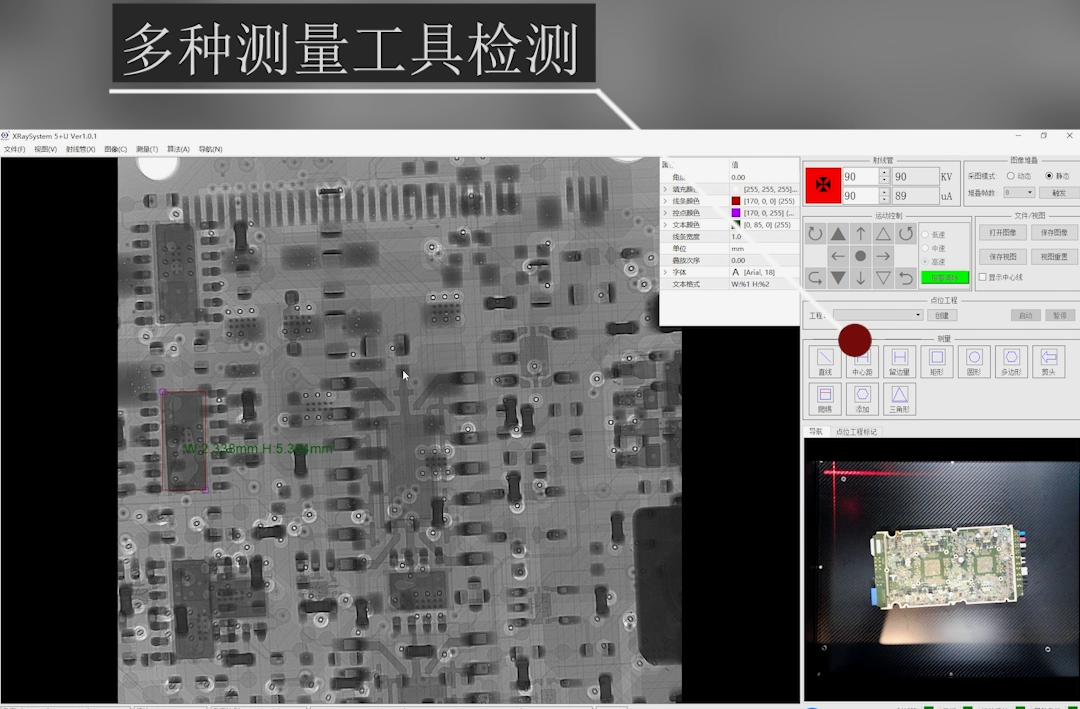

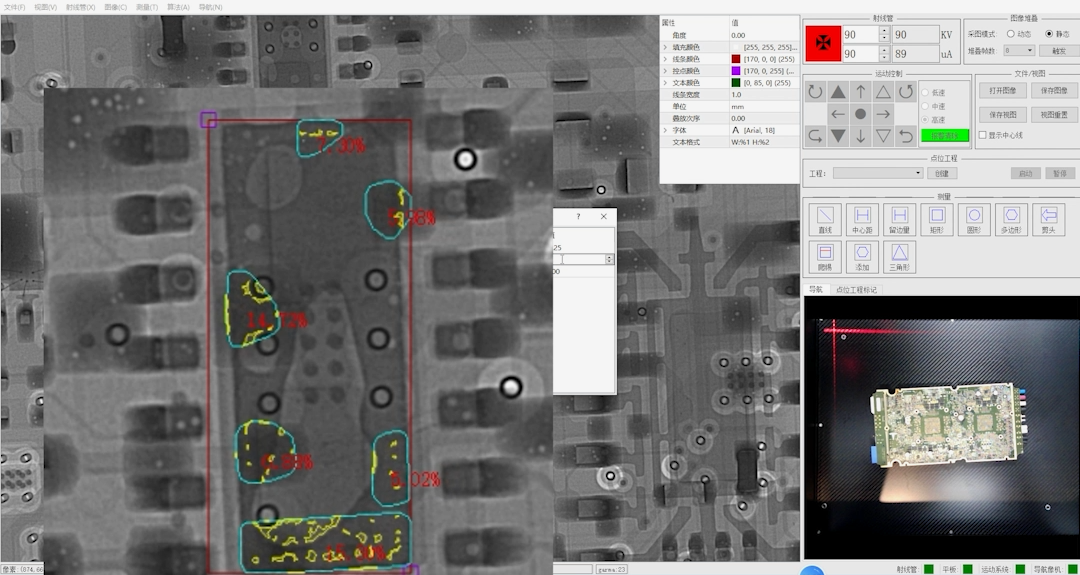

02 Void Rate Measurement Tools

Void rate is a key indicator for measuring welding quality. Wahfei X-Ray is equipped with professional measurement tools that can automatically calculate the percentage of bubbles within solder joints with one click. This data-driven inspection method provides factories with rigorous quality inspection report support.

Measurement Tool Interface Display

Automatic Void Rate Analysis Results

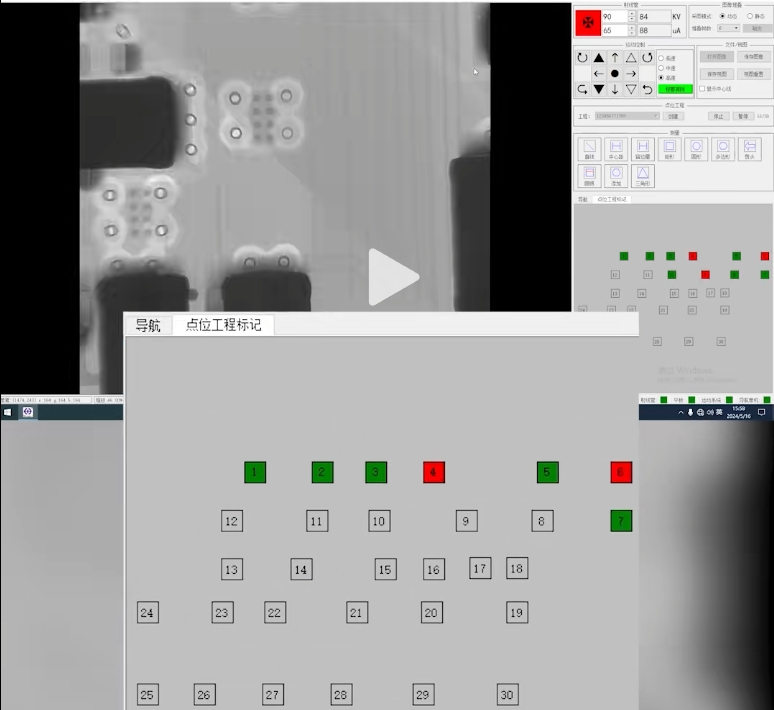

03Efficiency Doubled: CNC Automatic Programming Inspection

For high-volume factories, manual inspection is inefficient and prone to missed detections. The CNC automatic programming function of the Wahfei X-Mind system allows users to set a path once to achieve multi-point automatic inspection, significantly reducing labor costs and increasing inspection throughput.

CNC Automatic Programming to Improve Inspection Efficiency Demo

More Optional Functions: Meeting Diverse Inspection Needs

In addition, Wahfei X-Ray equipment provides a series of value-added modules to handle complex industrial scenarios:

| Optional Functions | Application Scenarios | Core Value |

|---|---|---|

| 360° Rotating Stage | Inspection of complex irregular parts and castings | All-round observation of internal structures |

| Intelligent Scanning System | MES system integration, traceability management | Achieve digital traceability with one code per board |

| Automatic Component Counting | SMT warehouse material inventory | Complete precise counting of thousands of materials within seconds |

Through modular configuration, you can customize the most suitable inspection solution based on your factory's actual budget and technical requirements.

Want to learn more about the detailed parameters of X-Ray inspection equipment?

Click the button below to visit our product details page and get professional technical support.

View X-Ray Product Details