Why is industrial X-Ray computed tomography (CT) particularly well-suited for inspecting injection-molded parts?

- Pubdate 2025-12-17

Industrial X-Ray Computed Tomography (CT) Technology Is Ideal for the Inspection of Injection-Molded Parts

Thermoplastic and thermosetting polymers processed through injection molding are widely used in common components such as bottle caps, storage containers, medical devices, electronic housings, and toys. Today, this advanced process is even capable of handling multi-material injection molding (two-shot or multi-color molding) to improve product density and rigidity, or to provide different colors, transparency levels, and surface textures according to specific design requirements.

However, since injection molding machines are designed for the mass production of identical parts, once the process is set up, it must be regularly validated to maintain consistent product characteristics. Injection-molded parts typically undergo visual inspection, mechanical strength testing, and sealing (waterproof) tests. In addition, achieving near-perfect plastic part geometry is often a lengthy process. Even though modern mold flow analysis tools are increasingly powerful, many factors still need to be optimized through actual measurement and analysis of prototype parts.

In accordance with commercial information agreements and respect for our partners’ intellectual property, the X-ray inspection images shown here are for technical capability demonstration only. Wahfei sincerely invites you to bring or send samples to experience the actual inspection performance of our equipment.

Why Is Industrial X-Ray Computed Tomography (CT) Particularly Suitable for Injection-Molded Part Inspection?

Although traditional inspection methods—such as coordinate measuring machines (CMM) point probing or optical scanning—can provide valuable results, in many applications they may require industrial CT as a complementary technique.

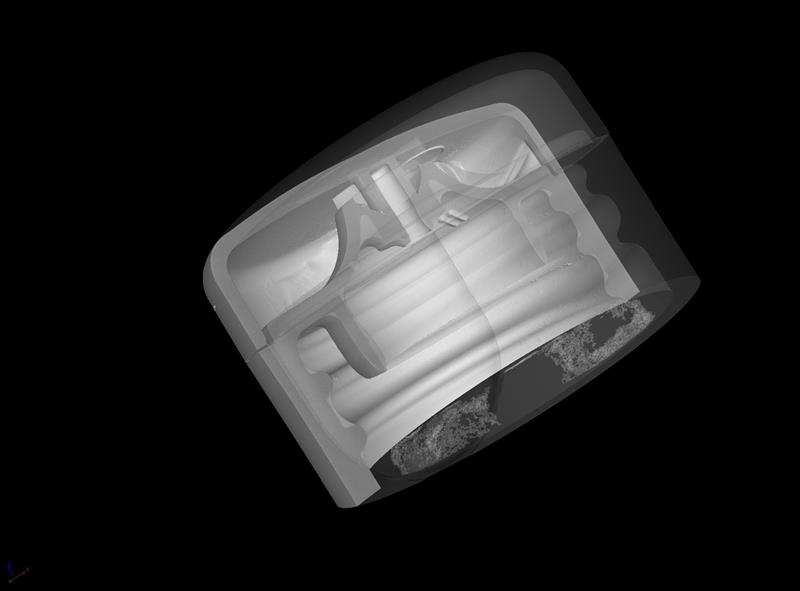

Due to the relatively low density of commonly used plastic materials, industrial X-Ray CT systems are especially well suited for inspecting plastic parts. Materials such as polyamide (nylon), polycarbonate, polyester, polypropylene, and polyethylene are easily penetrated by X-rays and generate very few artifacts. This means that obtaining both internal and external dimensions of parts using X-Ray CT technology is no longer a challenge: regardless of sample size, the results are highly accurate and achieved faster than with traditional techniques.

No Special Pre-Processing Required, High Degree of Automation

Unlike other technologies, X-Ray CT systems do not require any special pre-processing of the inspected sample. There is no need for contrast spray, marker placement, or probe path programming. Before starting the scan, the only requirement is to choose an appropriate orientation and secure the part in the system using a suitable fixture. After that, the entire process can run automatically and can be seamlessly integrated into fully automated robotic production lines.

From Reverse Engineering to Finite Element Analysis (FEA)

Using X-Ray CT systems, it is also very easy to generate meshes from both external and internal structures. The resulting point cloud data can be used as input for finite element models (FEM), compared with existing CAD models (nominal-to-actual comparison), or used to create new CAD data through reverse engineering workflows. Because real part geometries—including voids, porosity, high-density inclusions, or cracks—are taken into account during calculation, finite element analysis (FEA) can more accurately simulate mechanical stress, strain, displacement, or flow behavior.

Mold Optimization and Internal Quality Control

The results provided by industrial CT are extremely valuable for injection molding processes. Sampling inspections, prototype trials, first article inspection (FAI), and mold geometry optimization all have different inspection objectives at different stages.

Mold design optimization: One of the best ways to obtain the internal and external geometry of injection-molded prototypes is to use X-Ray CT systems. They can effortlessly generate a complete 3D mesh of the entire part, compare it with the CAD model, and measure warpage and shrinkage to guide mold modifications.

Internal material integrity inspection: Once mass production begins, defects such as trapped air, porosity/voids, and raw material inclusions in plastic injection-molded parts can be automatically detected and precisely located within seconds using X-Ray CT systems.

Wall thickness analysis and lightweighting: Thanks to the excellent penetration of X-rays in plastic materials, manufacturers can obtain 3D models of injection-molded parts and accurately measure wall thickness, helping engineers reduce part weight and achieve cost savings.

Want to confirm whether X-Ray inspection equipment meets your product or process requirements?

Wahfei Technology provides professional industrial CT inspection solutions and sample testing services.

Contact Us to Get an Inspection Solution