X-Ray Inspection for High-End Cosmetics like Lipsticks and Liquid Lip Tints & Plastic Packaging

- Pubdate 2025-12-19

Revealing Hidden Defects: How Industrial X-Ray Inspection Safeguards the Perfect Quality and Brand Integrity of Premium Cosmetics

Overview: In the premium cosmetics industry, brand reputation is built on flawless details. But how can you know whether a lipstick core has fractured without opening the package? Or detect inferior counterfeit refills hidden beneath an intact bottle cap? This article explains how non-destructive testing (NDT) enables effective quality control without compromising exquisite packaging.

For premium cosmetic brand owners and OEM manufacturers, “invisible risks” are often the most dangerous. A lipstick broken due to high temperatures during transportation, a microscopic gap at a lip gloss seal, or counterfeit products refilled into recycled authentic containers can all escalate into serious public relations crises in the age of social media.

Why Traditional Inspection Methods Fail to Meet Premium Cosmetics Requirements

Conventional inspection methods rely heavily on manual sampling or destructive unpacking. These approaches are inefficient and cannot ensure 100% inspection coverage. Especially for products with combined plastic and metal packaging—such as lipsticks and lip glosses—inspecting internal conditions while keeping the product sealed, untouched, and visually intact remains a critical industry challenge.

This is where modern industrial X-ray inspection systems deliver decisive value. Leveraging the superior penetration capability and density discrimination of X-rays, each product can be examined internally—much like a CT scan—without any physical contact.

Three Key Applications of X-Ray Inspection in Cosmetic Plastic Products

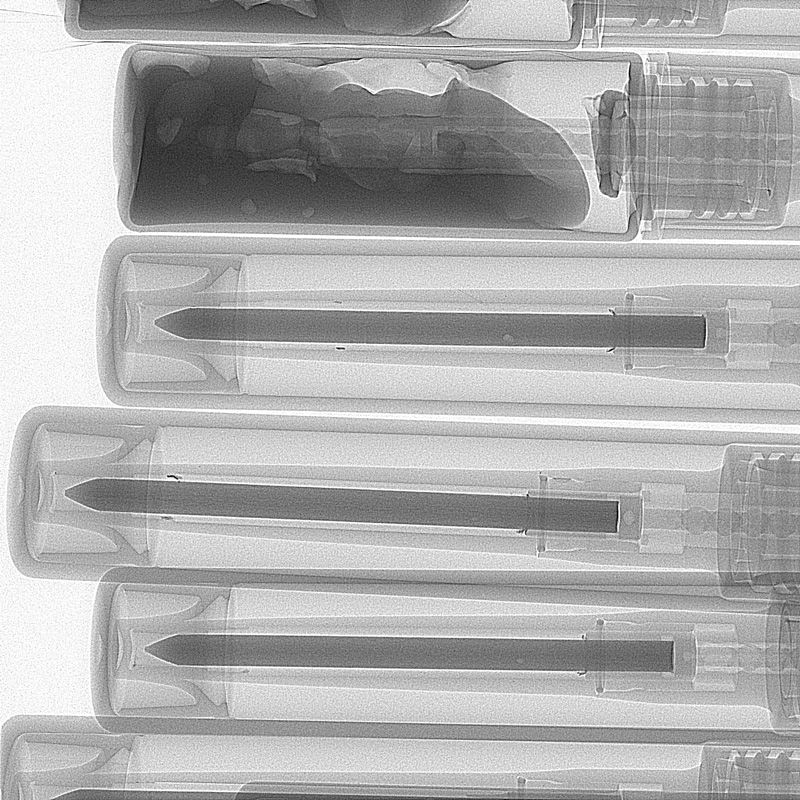

01. Non-Destructive Detection of Internal Defects

Challenge: Lipstick core breakage, air bubbles, deformation, or melting caused by high temperatures during transportation.

Solution: X-ray imaging clearly visualizes the internal shape of the cosmetic core, accurately identifying fractures and thermal deformation—ensuring that consumers receive a flawless product when they twist it open.

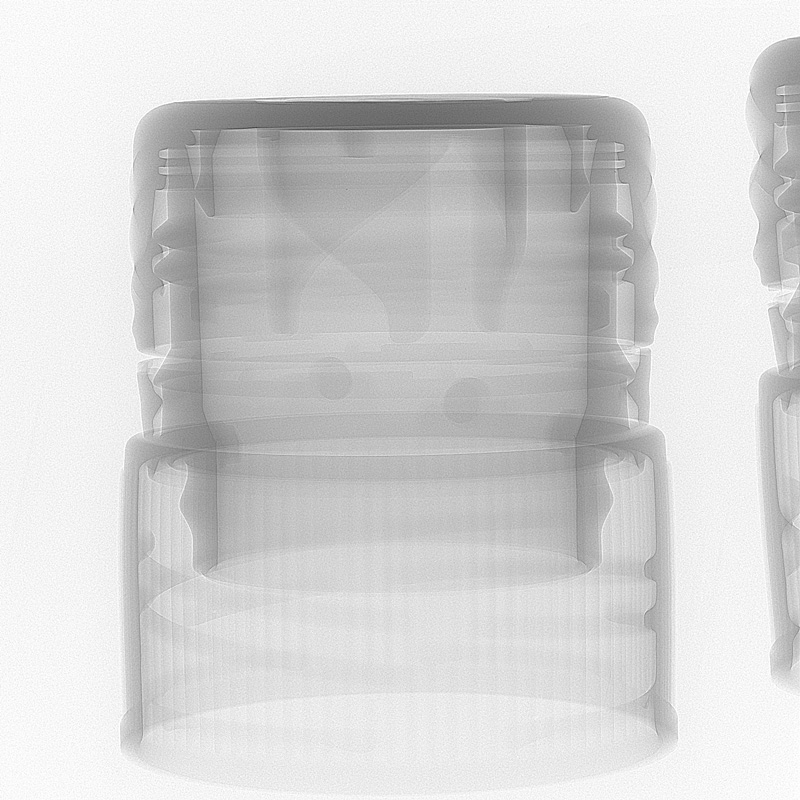

02. Seal and Packaging Integrity Inspection

Challenge: Loose bottle caps, missing sealing rings, and hidden leakage risks in lip gloss packaging.

Solution: By inspecting the engagement structure at the bottle neck, X-ray systems automatically determine whether the seal is properly secured, removing defective units and preventing leakage contamination during storage and logistics.

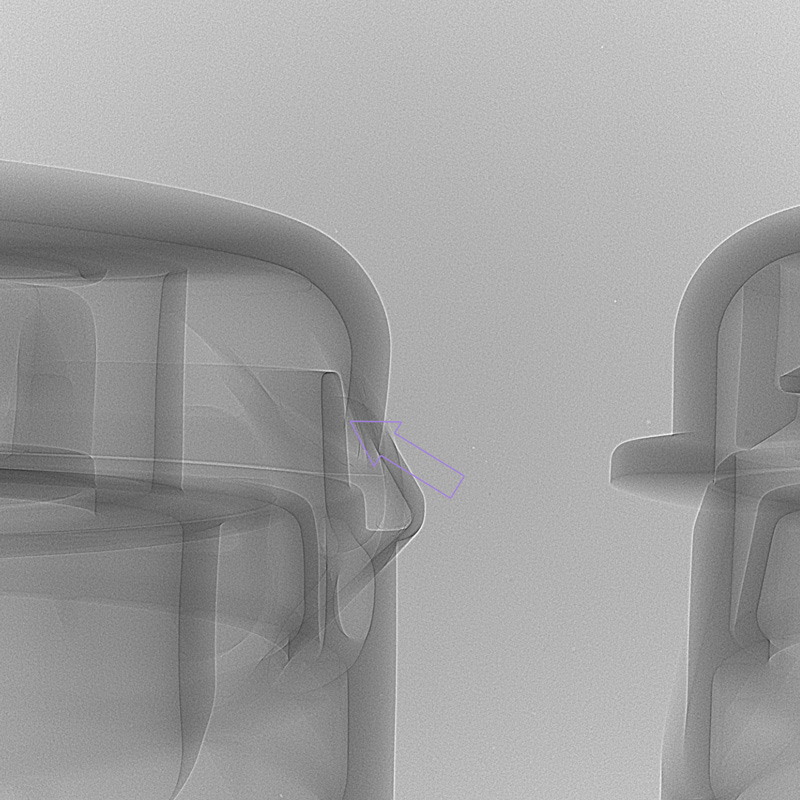

03. Anti-Counterfeiting and Authenticity Verification

Challenge: “Old bottles refilled with inferior products” by illegal resellers reusing original packaging.

Solution: X-ray inspection detects internal liquid levels and structural abnormalities, revealing signs of tampering or unauthorized opening to assist in authenticity verification.

Inspection Examples: What You See Is What You Detect

Lipstick Core Structure Inspection

Seal Status Visualization

Plastic Structural Integrity Analysis

*To comply with commercial confidentiality agreements and intellectual property protection, the industrial X-ray images shown here are for technical demonstration purposes only. Wahfei sincerely invites you to bring or ship samples to experience real inspection performance.

Concerned about batch quality? Want to validate inspection results?

Our engineers are ready to provide professional inspection solution recommendations.

Contact Us to Schedule a Trial Inspection