Solder Penetration Rate Inspection Standards and Requirements

Key Factors Affecting Solder Penetration Rate

It is important to note that specific penetration rate standards are not fixed but are influenced by a combination of factors:

Different types of audio products have varying requirements for signal transmission and electrical performance; professional-grade audio equipment typically demands higher penetration rate standards.

Operating temperature range, humidity conditions, vibration, and shock directly impact the reliability requirements of solder joints.

Some high-end customers or special application scenarios may propose customized penetration rate requirements that exceed industry standards.

Industry Practice: In the actual production process of audio chips, to ensure high product quality and long-term reliability, manufacturers often establish internal inspection standards that are more stringent than general industry standards, based on their own process capability levels and quality control systems. This approach helps reduce product defect rates, enhance customer satisfaction, and build a technological advantage for the brand.

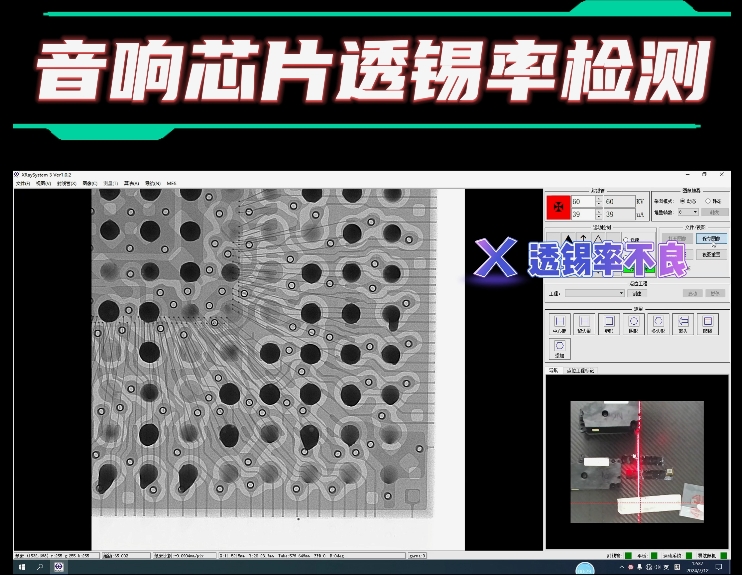

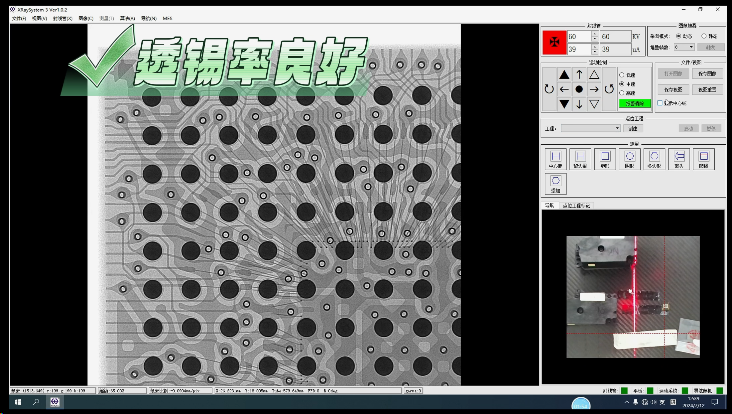

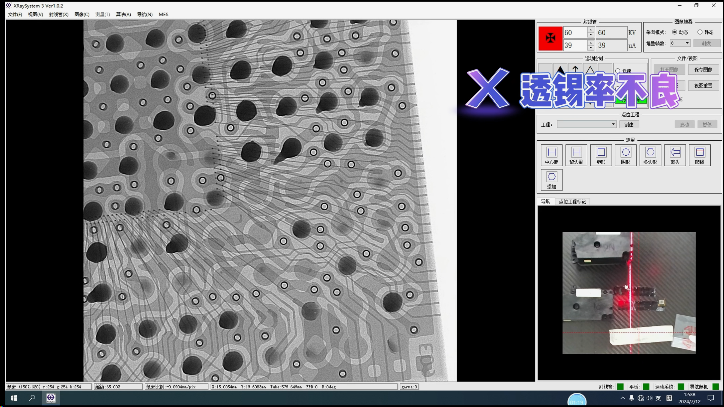

X-Ray Inspection Case Comparison

X-ray inspection technology (X-Ray Inspection) is a non-destructive testing method that can penetrate PCB substrates and components, clearly displaying the fill status of internal solder joints. Through X-Ray imaging, quality inspectors can accurately evaluate the solder penetration rate and identify soldering defects such as cold solder joints, voids, and bridging, ensuring each solder joint meets quality standards.

X-Ray inspection equipment's透视 imaging of audio chip solder joints

Qualified Standard Characteristics

• Uniform and full solder fill

• Penetration height ≥75% board thickness

• No significant voids or cavities

• Smooth and rounded solder joint edges

• Reliable and stable electrical connection

Common Defect Types

• Insufficient solder fill

• Penetration height<75% board thickness

• Presence of large voids/cavities

• Potential risk of cold solder joints

• Impacts long-term reliability

Key Points of Quality Control

X-Ray inspection technology has become an indispensable quality control method in modern electronics manufacturing. For high-precision electronic products like audio chips, strictly controlling the solder penetration rate not only ensures the mechanical strength and electrical performance of the solder joints but also effectively prevents potential issues during product use such as sound quality degradation, signal interference, and even complete failure.