Introducing the X-Ray Component Counting and Inspection System: Empowering the Electronic Components Supply Chain

- Pubdate 2026-02-03

Introducing the X-Ray Counting & Inspection All-in-One System to Empower the Precision Electronics Supply Chain

Image: Front desk view of Shenzhen Kexundawei Technology Co., Ltd.

Shenzhen Kexundawei Technology Co., Ltd. is an authorized spot supplier in China for multiple internationally renowned semiconductor manufacturers. The company is committed to providing comprehensive semiconductor product technical services to a wide range of industry partners. It professionally distributes and represents internationally recognized semiconductor brands such as ADI, TI, XILINX, ALTERA, LINEAR, and HITTITE. Its business covers CPLD/FPGA solutions across high-, mid-, and low-end segments as well as field-programmable logic technologies, high-performance DSP digital signal processing and ARM processors, PCI bus and USB interface technologies, FLASH memory, and intelligent power management technologies. Its products are widely applied in industries including military, aerospace, power and security, network communications, industrial control instrumentation, automotive electronics, and consumer electronics. Its partners include domestic trading peers, electronic product manufacturers, research institutions, and numerous multinational enterprises.

How the X-Ray All-in-One System Reshapes Electronic Component Management

By introducing the advanced X-Ray Counting & Inspection All-in-One System, enterprises can achieve fast and accurate counting of various electronic components. More importantly, it enables high-resolution non-destructive inspection of internal component structures. Potential quality risks can be identified before material warehousing or during production, ensuring product quality at the source.

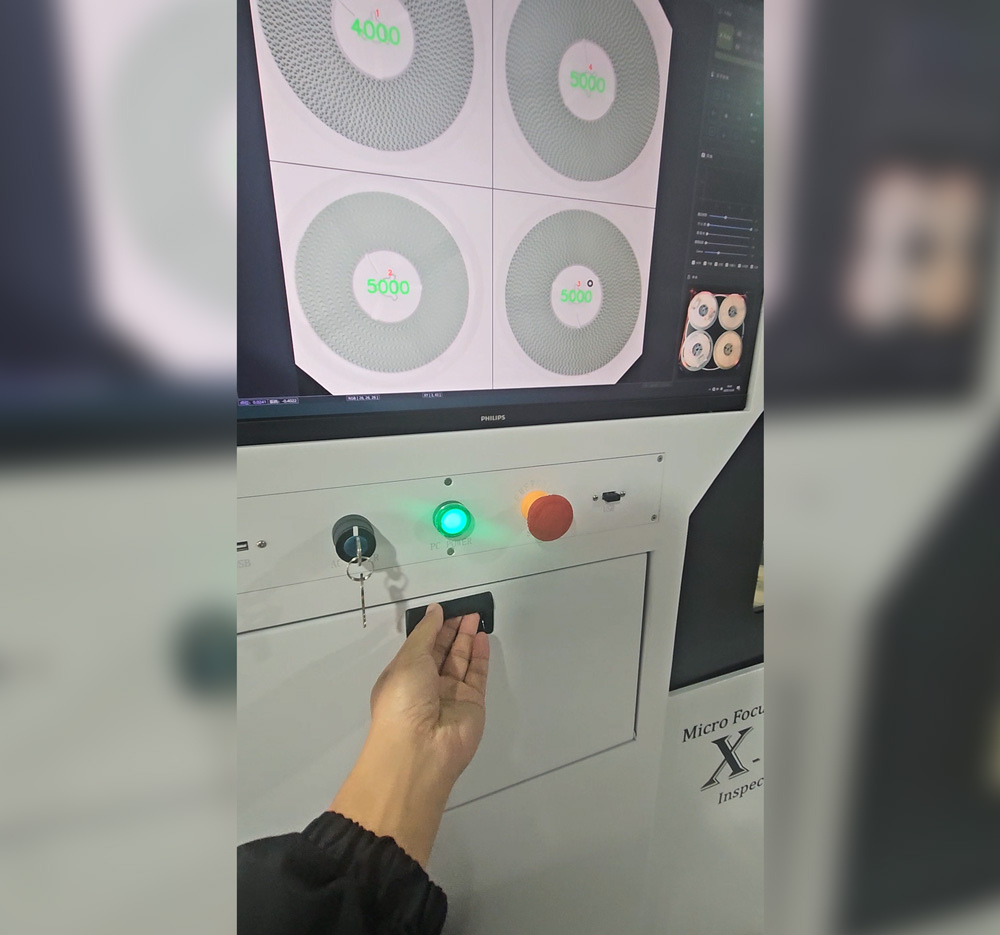

Image: X-Ray counting & inspection all-in-one system

Image: All-in-one counting system demonstration

Dual Function in One System, Doubled Value: Outstanding Advantages of an Integrated Solution

Compared with purchasing a standalone counting machine and a separate X-Ray inspection system, the integrated design of the X-Ray Counting & Inspection All-in-One System delivers significant comprehensive benefits. It not only optimizes capital investment, but also demonstrates unparalleled advantages in operational efficiency, space utilization, and data management.

| Comparison Dimension | X-Ray Counting & Inspection All-in-One System | Standalone Counter + Standalone X-Ray Inspection System |

|---|---|---|

| Equipment Investment | Significantly reduced initial procurement cost with a higher return on investment. | Higher initial procurement cost, requiring the purchase of two separate systems. |

| Floor Space | Highly integrated design that saves valuable factory or warehouse space. | Requires space for two separate machines, occupying a larger footprint. |

| Operating Process | Unified operating interface with simplified workflows and lower training costs. | Two independent systems with complex operation and separate training requirements. |

| Data Management | Seamless integration of counting and inspection data for easy traceability and analysis. | Independent data sets with difficult integration, leading to information silos. |

| Maintenance Cost | Unified maintenance reduces complexity and system downtime. | Separate maintenance for two systems increases complexity and cost. |

| Production Efficiency | Synchronized or rapid switching between counting and inspection significantly improves overall efficiency. | Materials must be transferred between two machines, resulting in waiting time and handling losses. |

Empowering the Future: Choose Intelligence, Choose Efficiency

Introducing the X-Ray Counting & Inspection All-in-One System is not only an equipment upgrade, but also a forward-looking strategic move in supply chain management and quality control. It marks a solid step toward improving operational efficiency, reducing operating costs, and ensuring product quality, enabling enterprises to deliver more reliable semiconductor products and technical services.

To learn more about the operational details of this system, please click: On-site Factory Operation Process of the X-Ray Counting & Inspection All-in-One System