Customer Case: X-Ray Inspection for Optical & Connector Components at Sunshine Technology

- Pubdate 2025-12-11

Background

Suzhou Sunshine Technology Co., Ltd. is a subsidiary of the Pinsiang Group. Headquartered in Taiwan, it has manufacturing facilities in Dongguan, Suzhou, Zhangzhou, and Vietnam, among others. Established in 2013 and located in the Wujiang District of Suzhou, the company primarily produces new electronic components such as optical communication transceiver module parts, connectors for industrial automation, as well as sensor components for automotive, communication, and consumer electronics applications.

Guided by the business philosophy of "Collective Effort, Pursuit of Excellence, Shared Success," the company continuously develops and innovates. It has been recognized as a High-Tech Enterprise in Jiangsu Province and houses a Suzhou Engineering Technology R&D Center. The company has also obtained certifications including ISO9001:2015, ISO14001:2015, ISO45001:2018, and IATF 16949.

Challenges and Inspection Needs

The complex internal structures of optical transceiver module components make it difficult for traditional inspection methods to comprehensively assess soldering quality and internal defects.

Precision electronic components like connectors require non-destructive testing to ensure product quality while preserving component integrity.

The high-quality demands in automotive, communications, and consumer electronics necessitate reliable solutions for internal defect detection.

There is a need to enhance production efficiency and quality control levels while reducing the defect rate.

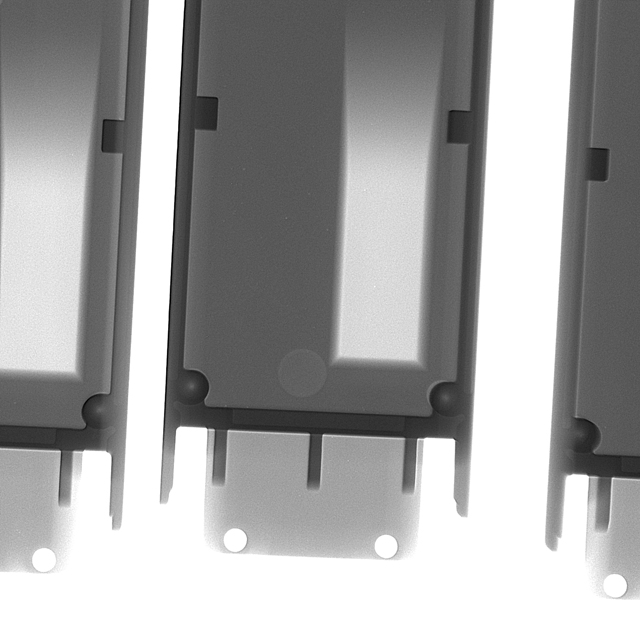

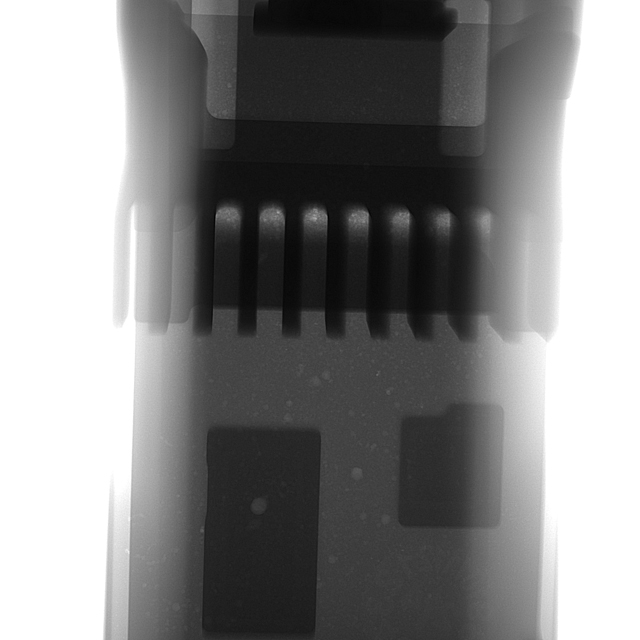

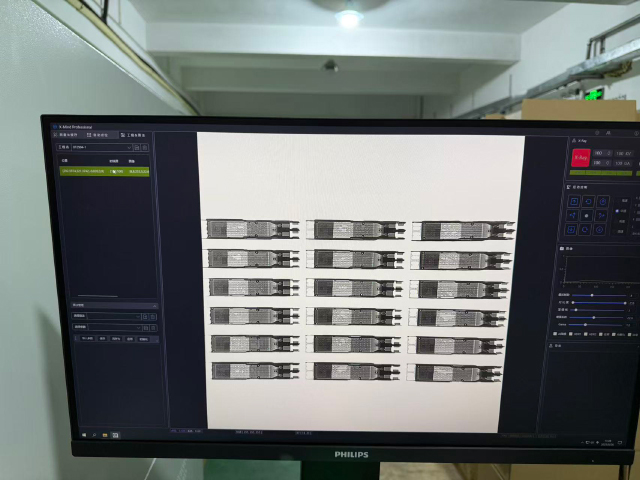

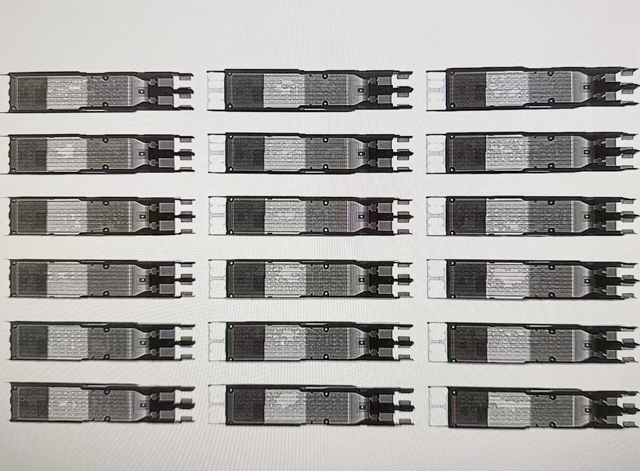

Industrial X-Ray Inspection

Wahfei's advanced Industrial X-Ray Inspection System offers high-resolution imaging capabilities, clearly revealing internal product structures. It accurately identifies quality issues such as soldering defects, cold solder joints, voids, and foreign object debris (FOD), providing robust technical support for product quality control.

X-Ray Inspection Technology Capability Showcase

In accordance with business information agreements and respect for our partners' intellectual property, the X-Ray inspection images displayed here are for the sole purpose of demonstrating technical capabilities. Wahfei cordially invites you to bring or send samples to experience the actual inspection performance of our equipment.

Core Advantages

High-Precision Inspection

Micron-level resolution for precise internal defect identification.

Non-Destructive Testing (NDT)

Non-destructive inspection preserves product integrity.

Fast and Efficient

Automated inspection significantly boosts production efficiency.

Data Traceability

Complete inspection records facilitate quality management and control.

Implementation Results and Value

Significantly improved the accuracy of quality inspection for optical modules and connectors.

Effectively reduced product defect rates and increased customer satisfaction.

Enhanced quality control capabilities within the production process.

Provided strong support for the high-quality requirements in automotive, communications, and consumer electronics sectors.