Leoni Electrical acquires X-ray inspection equipment for cable harnesses

- Pubdate 2026-02-04

LEONI is a global supplier of energy and data management products, solutions, and services for the automotive industry. The group operates in 21 countries with approximately 87,000 employees, serving customers across the global automotive, commercial vehicle, and component supply industries. It is one of the world’s largest suppliers of complex wiring systems and customer-specific cable harnesses. LEONI China operates four major production bases: five plants in Langfang, two plants in Jining, two plants in Tieling, and one plant in Penglai. With more than 166,000 square meters of production space, around 3,000 employees are dedicated each day to manufacturing high-quality wiring harness systems that power global mobility.

Truly “Visible” Inspection Capability in Cable and Wire Harness Quality Control

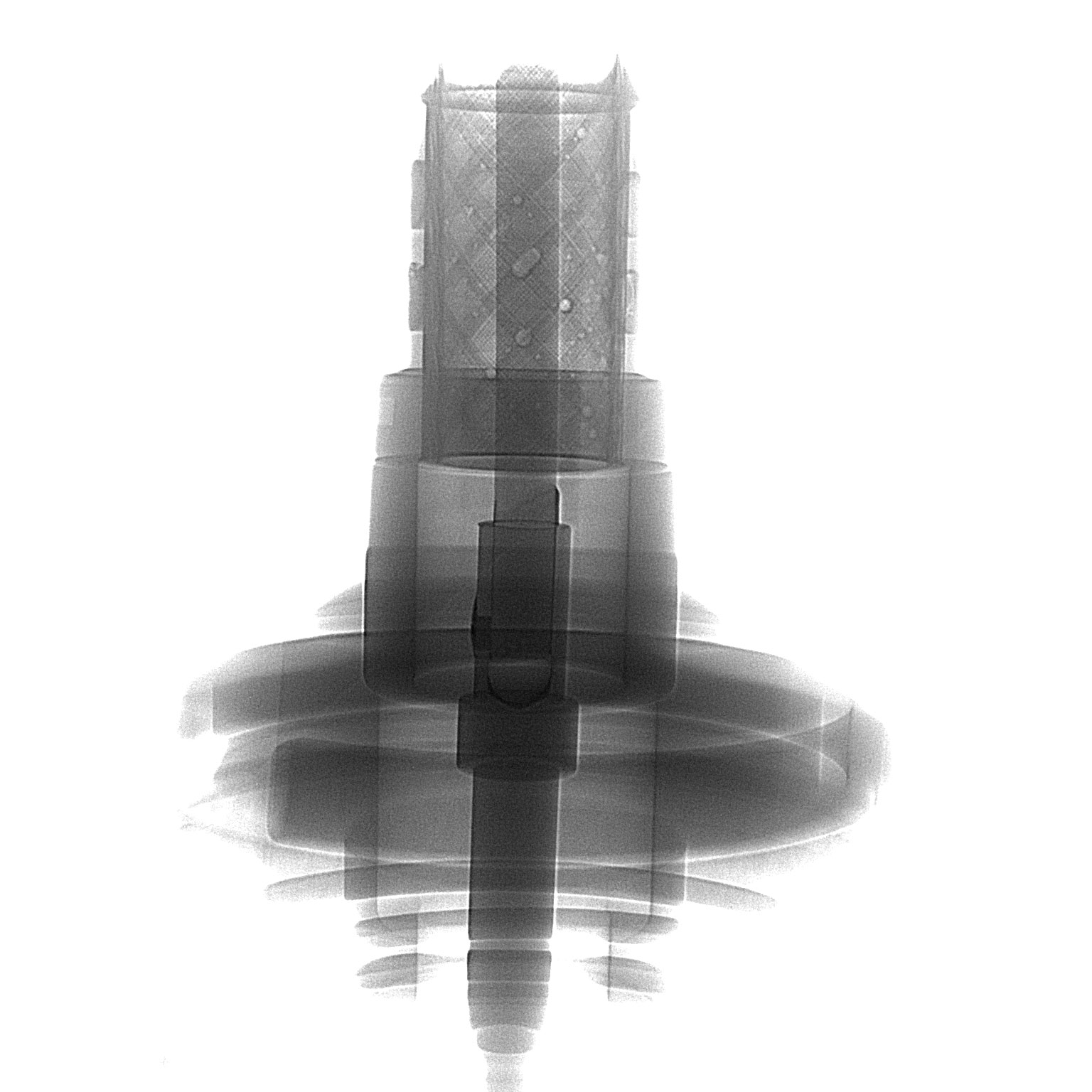

In the manufacturing of high-density cable and wire harnesses, the factors that truly determine reliability are often not visible on the surface. Conductor misalignment, insufficient terminal crimping, concealed internal breaks, or foreign matter entrapment—once these issues flow into downstream assembly processes, they often result in system-level rework or even batch-level risks. Relying solely on sampling inspections or electrical performance testing makes it difficult to comprehensively cover such structural hidden hazards.

It is precisely under these manufacturing realities that the value of X-Ray inspection equipment becomes evident. Rather than simply replacing manual inspection, it provides quality teams with a means of “structural-level verification.” Through X-ray imaging, conductor alignment, bending radius, and internal terminal conditions can be directly visualized, transforming issues that once relied on experience-based judgment into objective information that is visible and verifiable.

For wire harness products manufactured in parallel across multiple specifications and models, this inspection method also significantly reduces changeover costs. Structural differences no longer depend entirely on operator proficiency, but are instead evaluated consistently through imaging standards, helping maintain stable quality output under mass production conditions.

From a longer-term perspective, introducing X-ray imaging inspection essentially completes a “structural validation” earlier in the manufacturing process. It keeps issues at a stage where they can still be corrected, rather than allowing them to surface later during vehicle assembly, operation, or even in the market.