Industrial X-Ray Inspection for SMD and FPC Assemblies with Hidden Solder Joints

- Pubdate 2025-12-24

Industrial X-Ray Inspection Equipment for Non-Destructive Evaluation of SMD-FPC Solder Joints

In applications where flexible printed circuits (FPC) are combined with SMD components,

solder joints are often located beneath substrates or component bodies,

making them inaccessible to visual inspection or conventional AOI.

To reduce potential failure risks in mass production,

Kunshan Weimei introduced industrial-grade X-Ray inspection equipment

into its in-line quality control process,

enabling non-destructive inspection and process evaluation of SMD-FPC assemblies.

Typical Challenges in SMD-FPC Solder Joint Inspection

Solder joints are located under FPC cover layers or component bodies and are not visible externally

Small pad sizes impose strict requirements on solder volume and placement accuracy

Multi-layer or flexible structures make internal solder joint conditions difficult to evaluate

Sampling inspection cannot effectively reflect consistency across mass production

Practical Role of Industrial X-Ray in SMD-FPC Inspection

By utilizing X-ray penetration imaging,

industrial X-Ray systems enable non-destructive visualization of internal solder structures

without damaging the product,

supporting the identification of the following common issues:

Insufficient solder volume or abnormal solder distribution

Voids and porosity within solder joints

Alignment conditions between pads and component leads

Local bridging or abnormal soldering areas

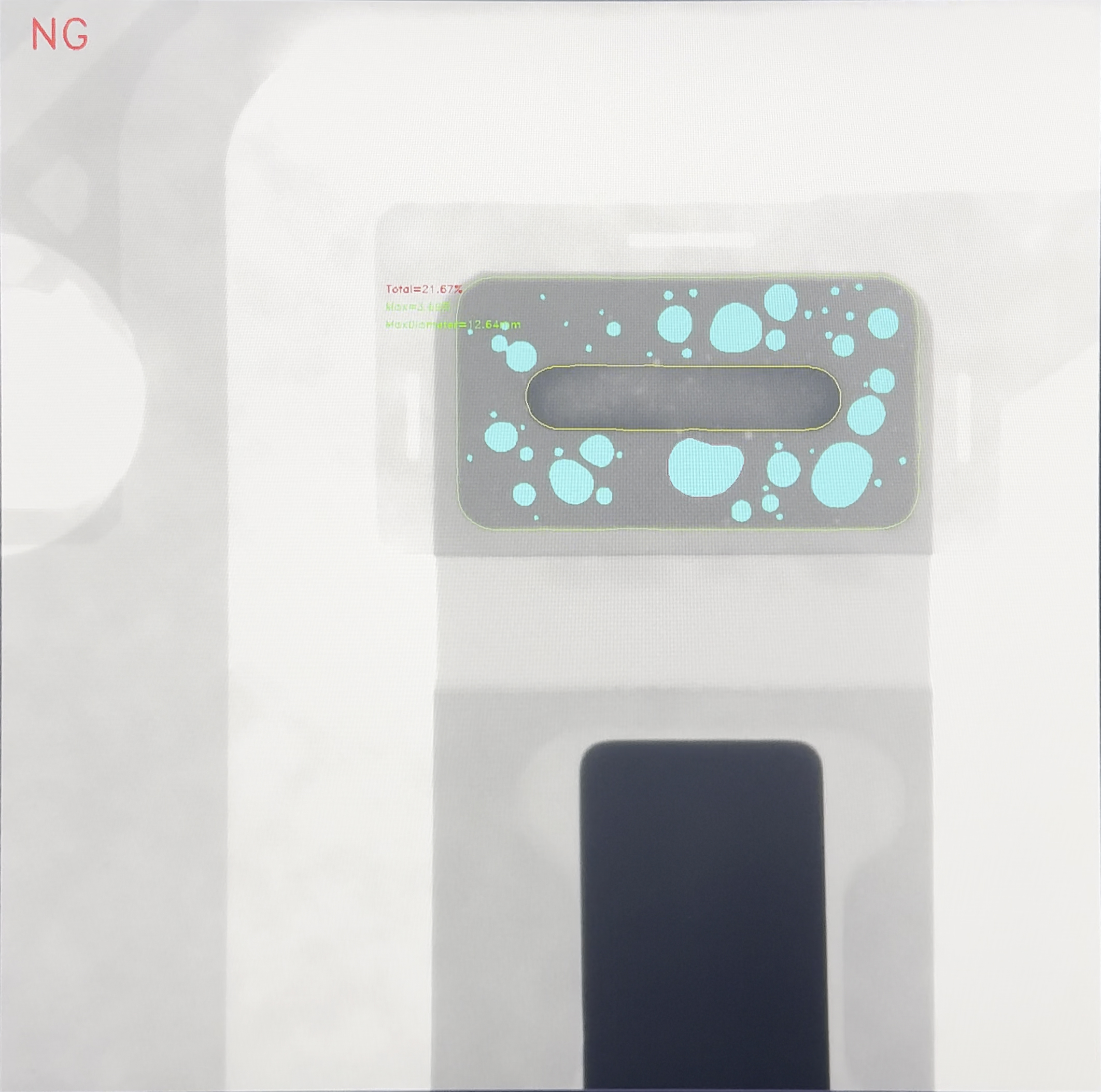

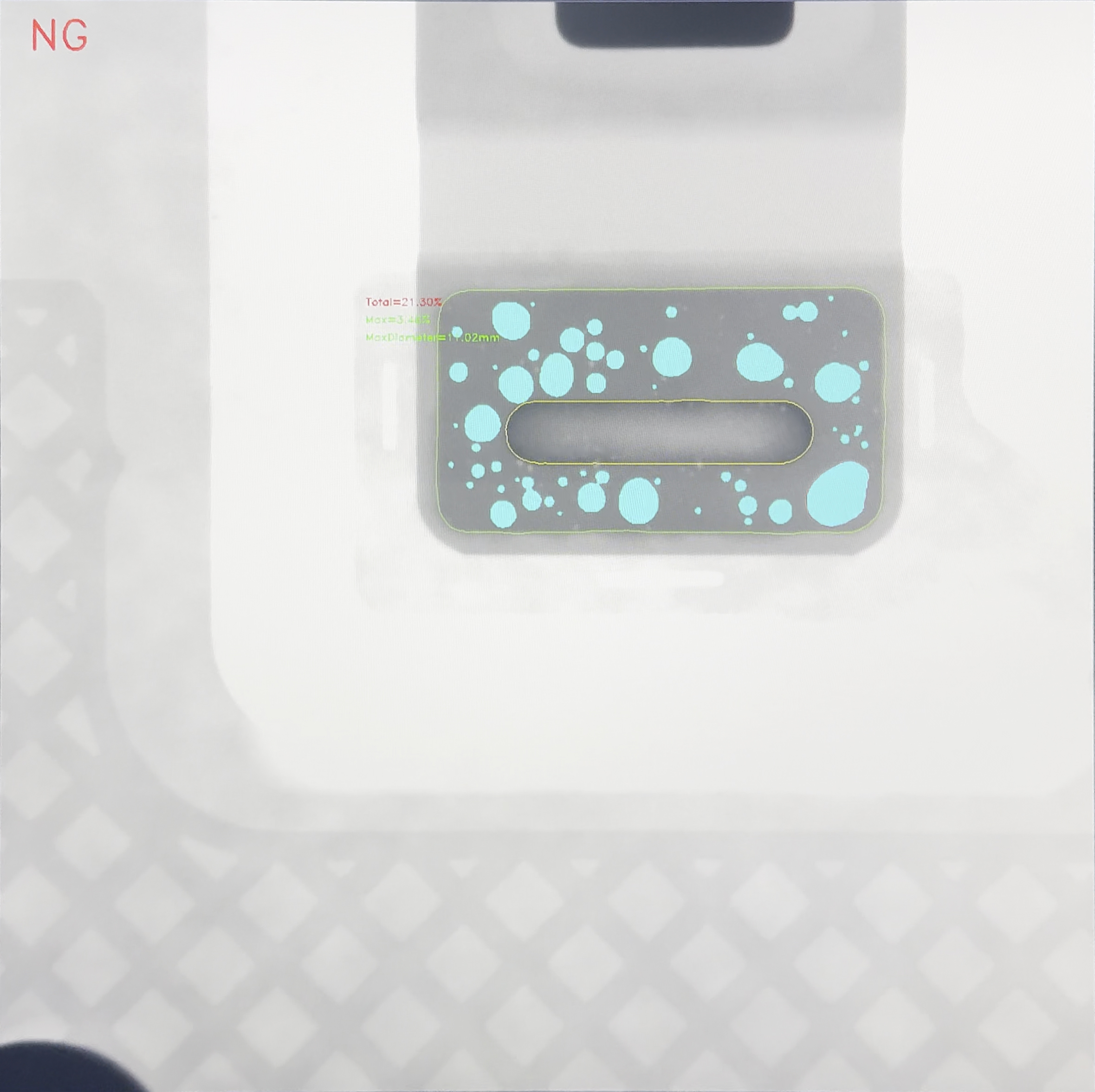

X-Ray Inspection Image Examples

|  |  |

In compliance with commercial information agreements and intellectual property protection,

the X-Ray images shown here are for technical capability demonstration only.

Wahfei sincerely invites you to bring or send samples to experience actual inspection results on your products.

Inspection Value

By introducing industrial X-Ray inspection at critical process stages,

manufacturers can identify potential soldering issues earlier during mass production,

providing objective data support for process optimization and quality decisions,

while reducing rework costs and customer complaint risks.