X-Ray Inspection of BGA Defects | Video Demonstration

- Pubdate 2025-12-27

X-Ray Inspection of BGA

Traditional top-down X-Ray inspection systems can no longer detect many common BGA defects. With the widespread application of BGA, flip-chip, and leadless package devices, inspection has upgraded from "seeing" to "seeing accurately and seeing through".

Hua Fei's X-Ray inspection system is designed for this. The system supports real-time, off-axis X-Ray imaging, suitable for online inspection and failure analysis of PCBA and array-type devices. The sample can achieve 360° rotation and large tilt observation, helping engineers quickly identify the most challenging soldering defects.

Head-in-Pillow Defect Analysis

The "head-in-pillow" effect is named because the solder ball shape resembles "a head resting on a pillow". This defect occurs under BGA devices, when the solder ball and solder paste fail to form a reliable metallurgical bond during the reflow process.

Main reasons include: the solder ball and solder paste fail to make effective contact during the reflow stage, or the flux activity is insufficient, unable to remove the oxide layer on the solder surface. These issues are often closely related to alignment accuracy, coplanarity, solder paste management, and reflow profile.

In some cases, the solder ball remains a regular sphere, while the surrounding solder joints appear "gumdrop-shaped", which usually means that the solder ball did not form a true soldering connection with the PCB pad, belonging to a typical open circuit defect.

Void Analysis

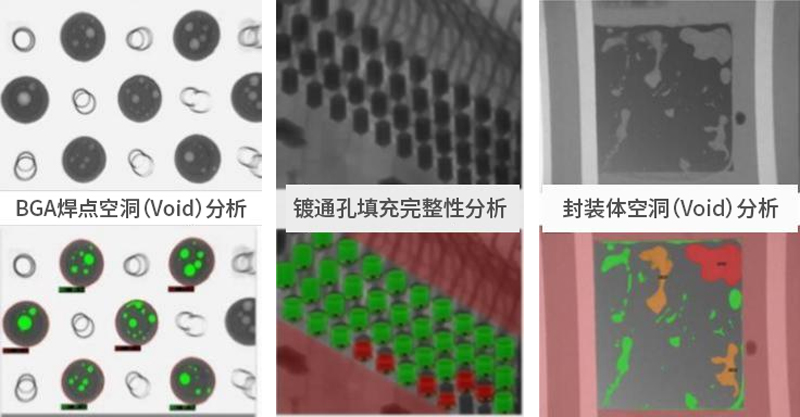

The X-mind system integrates real-time void analysis capabilities, which can be used for:

• BGA solder ball void ratio statistics

• Bottom termination device (BTC) ground end void analysis

• PTH (plated through-hole) fill completeness evaluation