X-Ray Inspection of Corrugated Hose Welds

- Pubdate 2026-01-24

In modern industry, corrugated hoses (also known as metal bellows, metal corrugated hoses, or expansion joints) play a critical role. Their applications span key fields with high pressure, high temperature, and stringent safety requirements, such as aerospace, petrochemical processing, nuclear energy, and vacuum technology. The performance and service life of corrugated hoses depend almost entirely on their weld quality.

1X-Ray: The Ultimate Tool for Corrugated Hose Weld Inspection

Among various non-destructive testing methods, X-ray inspection, with its unique “see-through” capability, is widely regarded as one of the most reliable means for quality control of corrugated hose welds.

Why Do Traditional Methods Fall Short?

Surface inspection methods (such as PT and MT) can only detect surface-breaking defects. However, internal defects generated during welding—such as porosity, slag inclusions, and lack of fusion—are the true “invisible killers.”

The Core Advantages of X-Ray

Based on differential absorption of X-rays by materials. It not only detects defects, but also accurately identifies their type, location, size, and severity.

“X-ray inspection enables integrated imaging and analysis of the inspected object from surface to interior. This comprehensive ‘medical check-up’ is the only reliable safeguard for zero leakage under high-pressure operating conditions.”

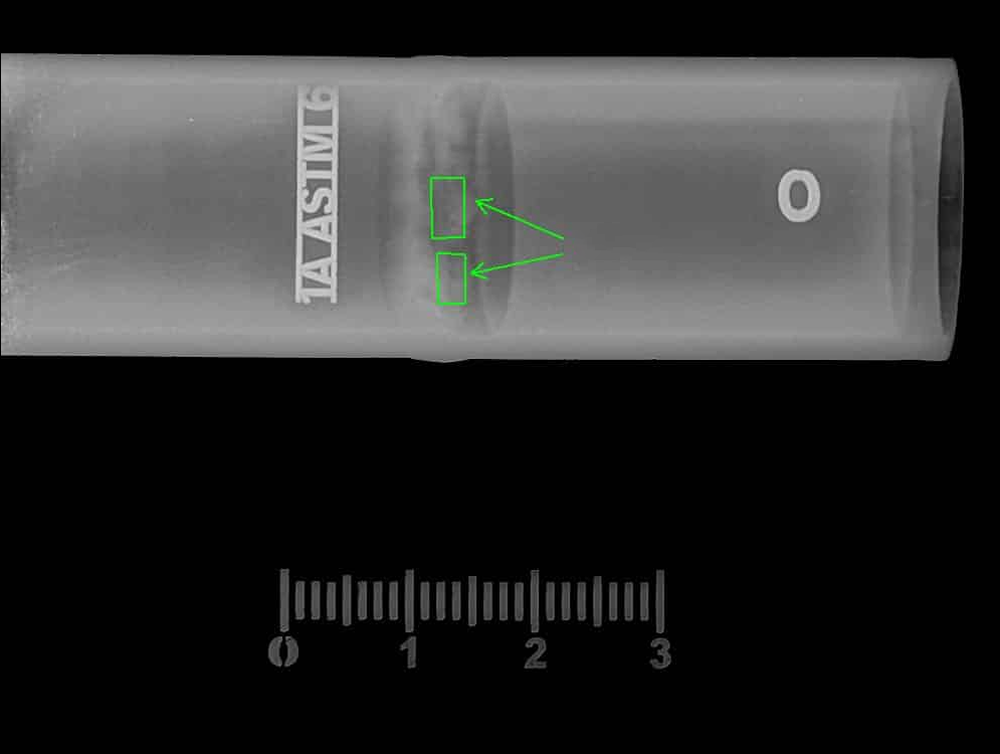

Figure: X-ray imaging example of corrugated metal hose welds

2How X-Ray Ensures Corrugated Hose Quality

3Practical Insights: X-Ray Identification of Common Welding Defects

● Porosity

Characteristics: Circular or elliptical dark spots.

Impact: Reduced density, creating potential leakage paths.

● Inclusions

Characteristics: Irregular gray shadows.

Impact: Disruption of metal continuity and reduced strength.

● Lack of Penetration

Characteristics: A dark linear indication along the centerline.

Impact: Severe strength deficiency, leading to premature failure.

● Cracks

Characteristics: Thin, elongated dark lines with sharp edges.

Impact: Highly prone to propagation, leading to sudden fracture.