X-Ray Component Counting & Inspection Combo Machine — Official Operation Guide

- Pubdate 2026-01-23

X-Ray Material Counting and Inspection Integrated Solution

In electronic manufacturing, SMT incoming inspection, and semiconductor packaging processes, X-Ray inspection equipment does more than simply “see inside structures.” It directly affects material counting accuracy, inspection efficiency, and the stability of downstream processes. To address the issues of low efficiency, high error rates, and the inability of traditional manual counting to simultaneously detect internal defects, integrated X-Ray solutions that combine material counting and inspection are increasingly becoming standard equipment for many enterprises.

Real Operation Video Demonstration by X-Ray Material Counting and Inspection Equipment Manufacturer

The video above shows a real operation demonstration of Wahfei’s X-Ray material counting and inspection integrated equipment, fully presenting the actual workflow from material counting to inspection and void analysis.

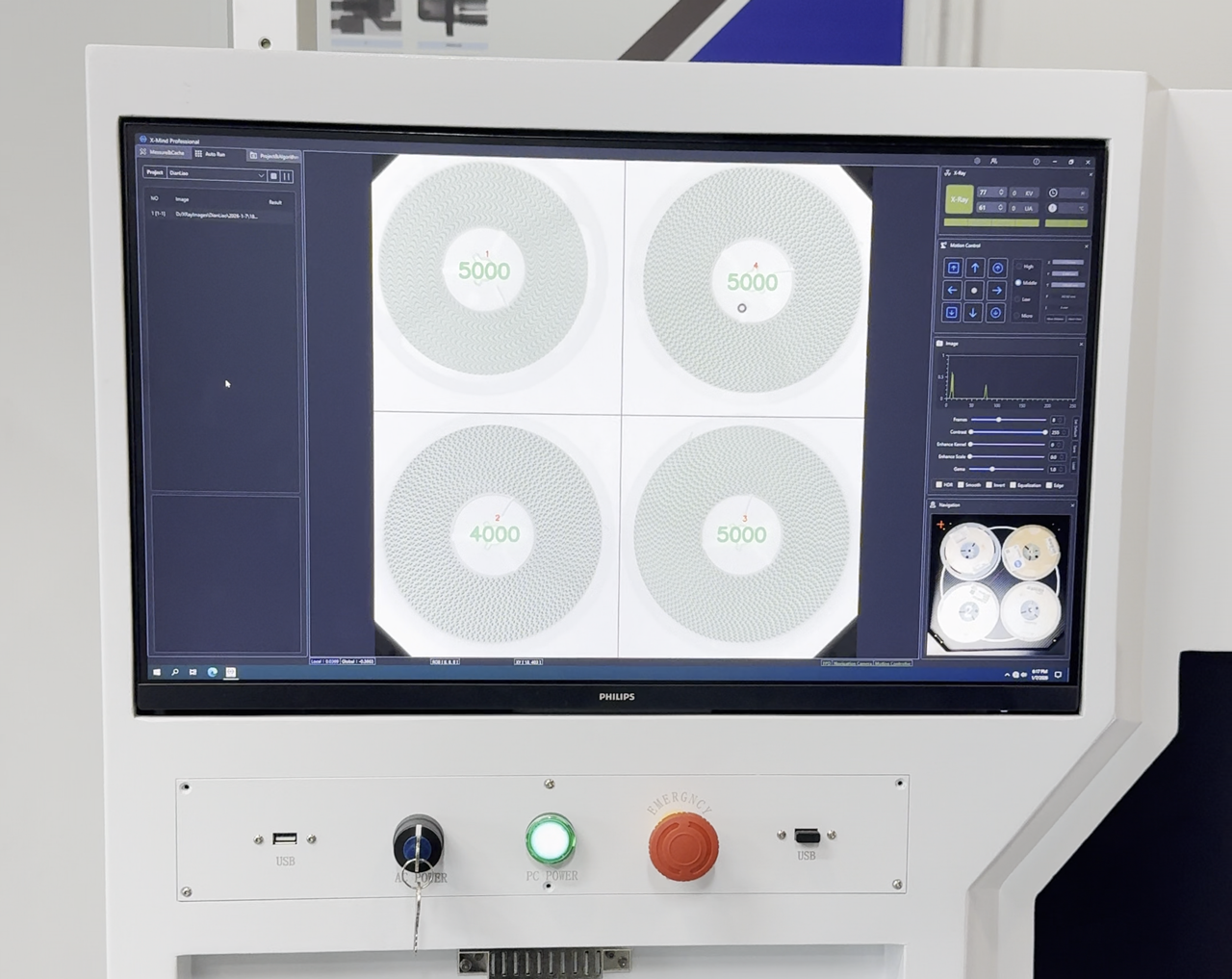

X-Ray Material Counting Mode

In material counting mode, the core objective of the system is to quickly and accurately identify material quantities while avoiding unpacking and manual intervention.

During operation, the product to be counted is placed steadily on the sample stage. After closing the protective cabinet door, the start button is activated via the software interface. The X-Ray system then runs automatically, completing X-ray emission, imaging, and intelligent recognition, and outputs clear counting results within a short time. This is especially suitable for high-density materials such as IC reels and tray-packaged components.

X-Ray Inspection Mode

When non-destructive inspection of internal structures is required, the system can be switched to inspection mode. This mode mainly addresses challenges such as invisible solder joints, complex internal structures, and difficult defect localization.

After placing the product on the sample stage, click the X-ray source power switch. Then, double-click the target position in the viewing or navigation window. The system will automatically complete positioning and quickly move to the region of interest, significantly reducing operational complexity.

During imaging, operators can freely adjust system parameters such as contrast and brightness according to inspection requirements, and zoom in or out at any magnification to ensure that fine structures and potential defects are clearly visible.

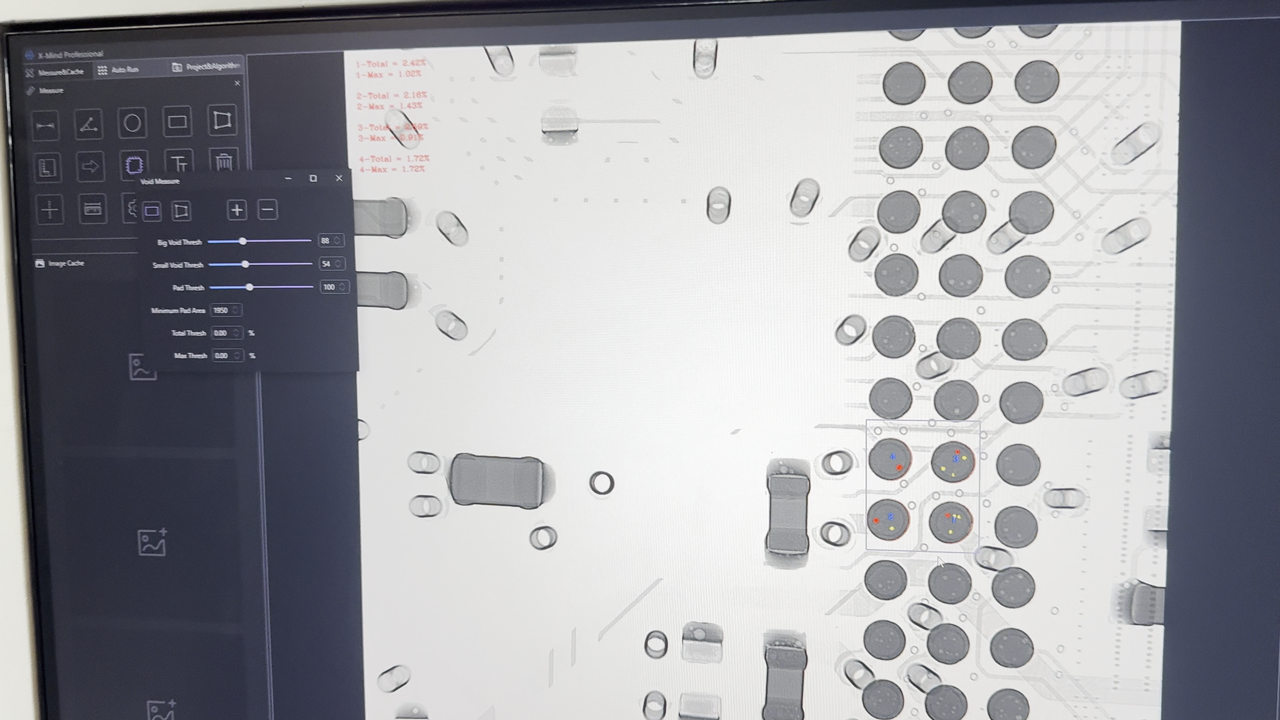

Void Inspection Process Explanation

For applications with high solder joint reliability requirements, such as BGA, QFN, and power device packaging, X-Ray void inspection is a key basis for evaluating soldering quality.

After inspection is completed, the X-ray source is turned off. The system then analyzes internal voids within solder joints based on the acquired X-Ray images, helping engineers determine whether the soldering process meets quality standards.

After inspection, remove the sample to complete the entire X-ray inspection process, achieving an efficient closed loop of material counting and quality evaluation.

Recommended X-Ray Equipment Solutions

In response to the practical needs of electronic manufacturing enterprises for incoming material counting and non-destructive inspection, Wahfei has launched a mature and stable X-Ray inspection system — XC9100 X-Ray Material Counting and Inspection Integrated System. It delivers outstanding performance in material counting accuracy, imaging clarity, operational efficiency, and safety protection, and is widely applicable in industries such as SMT, semiconductors, and integrated circuits.