About us

About us

Shenzhen Wahfei Technology Co.,Ltd.

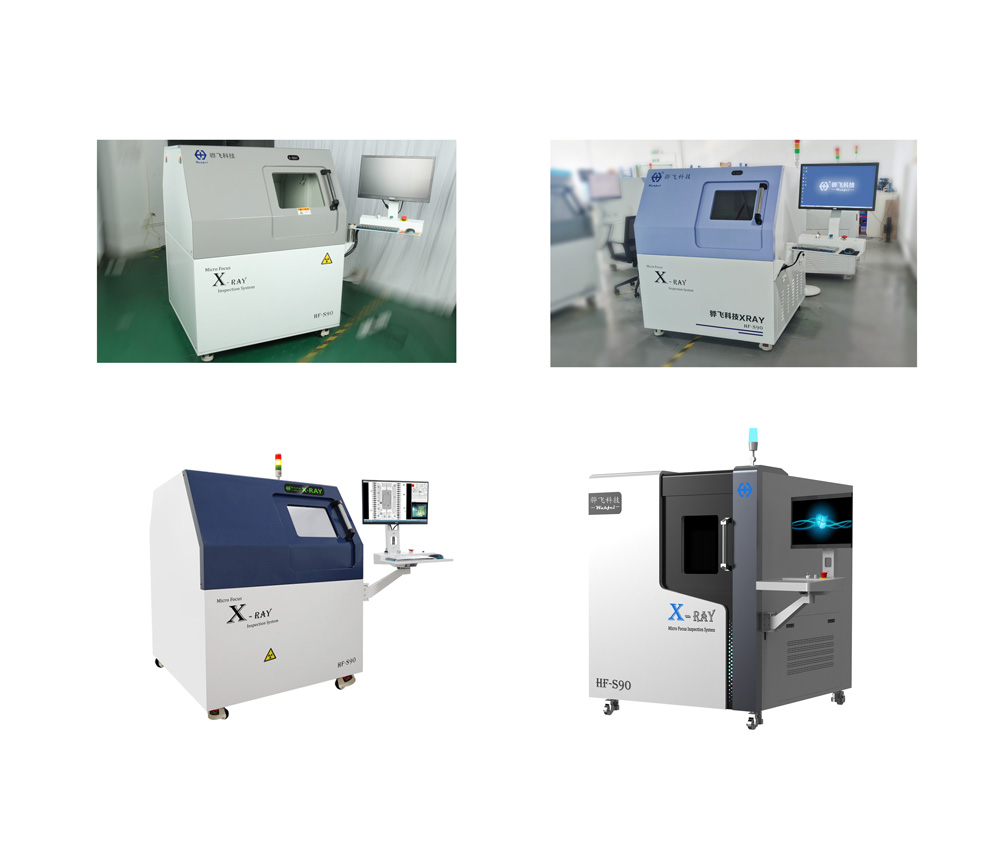

Shenzhen Wahfei Technology Co.,Ltd.,established in 2018,is a high-tech enterprise specializing in industrial X-Ray intelligent inspection technology.The company is dedicated to providing high-precision and high-efficiency non-destructive testing(NDT)solutions for the manufacturing industry.Building on X-Ray imaging inspection and driven by advanced image processing and AI applications,Wahfei has developed a comprehensive full-stack intelligent inspection system that integrates hardware,software,and data.

Read more

News

2025-12-11

Customer Case: X-Ray Inspection for Optical & Connector Components at Sunshine Technology

Suzhou Sunshine Technology, a manufacturer of optical modules and connectors, utilizes advanced industrial X-ray inspection systems for non-destructive quality control. See how X-ray technology ensures internal integrity and detects defects in精密电子组件. Learn about their inspection solutions.

2025-12-04

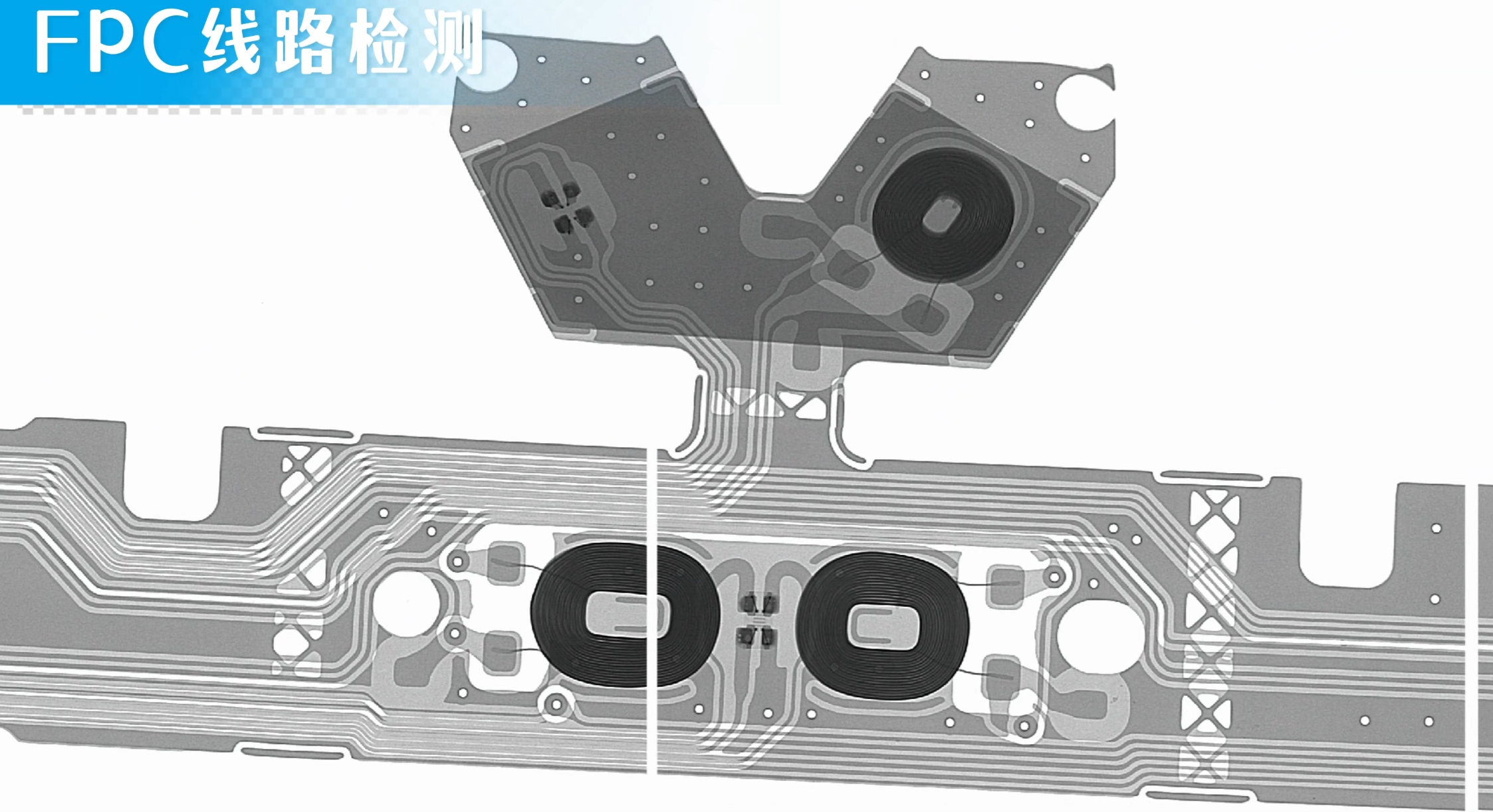

Fuzhisheng Acquires X-Ray Equipment for FPC Inspection

With the introduction of the Wahfei HF-S90 six-axis multifunctional X-ray inspection system, Ji’an Fuzhisheng now performs full-process, non-destructive penetration inspection on FPC assembly, significantly reducing the risk of batch rework caused by hidden defects and delivering IPC-compliant quality assurance for high-reliability industries such as consumer electronics and automotive electronics.

2025-11-15

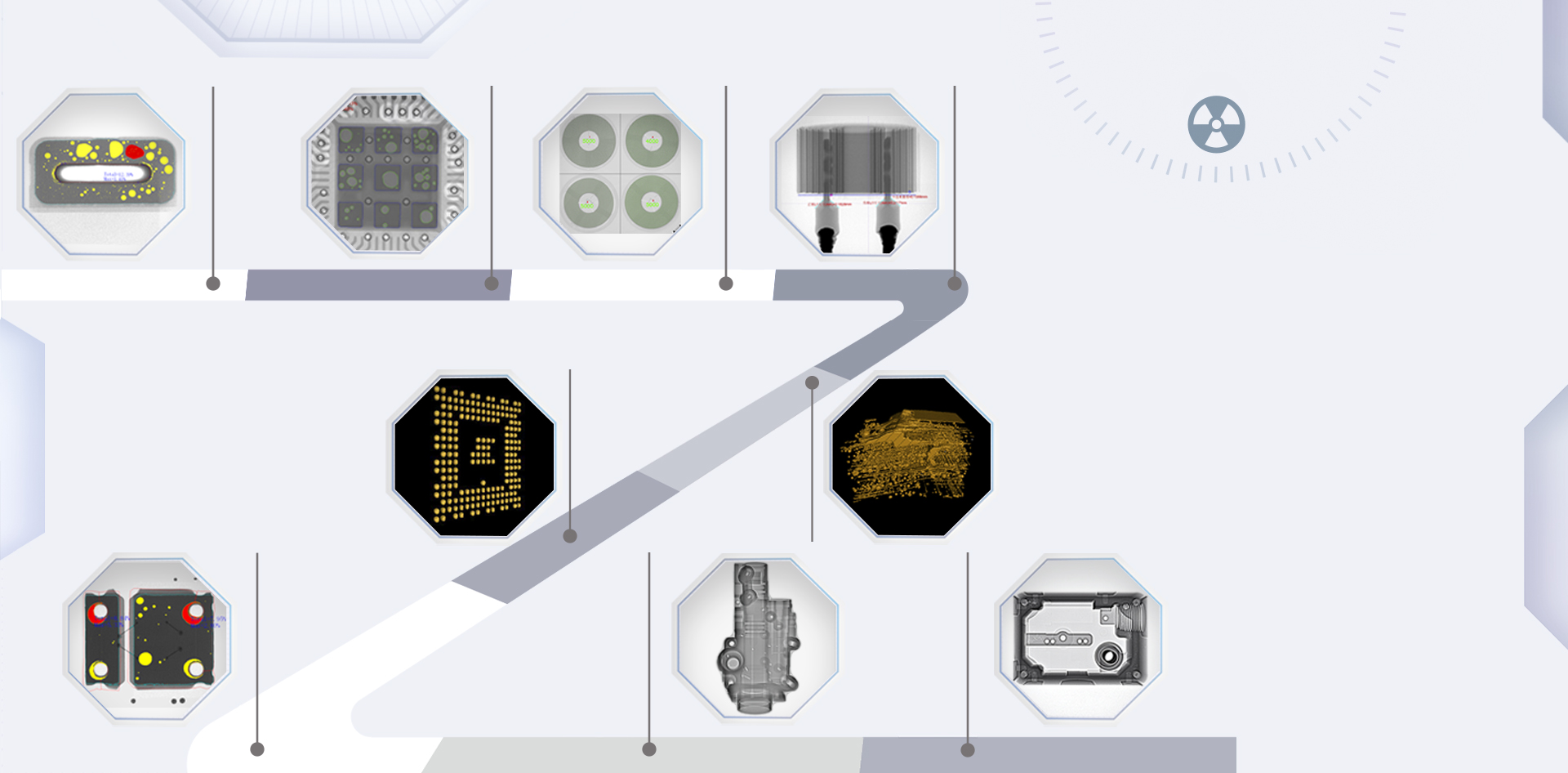

The Evolution of X-Ray Inspection Equipment: Witnessing the Innovative Transformation of the HF-S90

As Wahfei's most representative offline X-Ray inspection equipment, the HF-S90 has undergone four iterations over seven years. Each upgrade represents not just an improvement in appearance, but a comprehensive leap in performance, structure, and intelligence. For you, this means higher inspection accuracy, faster inspection speeds, and more stable production assurance.

2025-11-04

Huizhou Kaiyuan Purchases X-Ray Equipment for Battery Inspection, Enhancing Quality Assurance Case Analysis

To address the industry challenge of detecting internal defects in lithium batteries, Kaiyuan New Energy has introduced Wahfei X-Ray inspection equipment, enabling non-destructive imaging of internal battery structures, effectively reducing defect outflow rates and ensuring product safety and consistency.

2025-07-31

Focusing on X-Ray Non-Destructive Testing Wahfei Tech Debuts at the 19th CSDD Conference

With the accelerated adoption of third-generation semiconductors like silicon carbide (SiC) and gallium nitride (GaN), alongside the boom in new energy vehicles, photovoltaic energy storage, and AI data centers, the industry's demand for efficient and precise chip testing is continuously growing. From July 25th to 27th, 2025, the 19th China Semiconductor Discrete Devices Conference & Exhibition was held under the industry's spotlight. Wahfei Technology made a significant appearance, showcasing its independently developed full-stack X-Ray intelligent inspection solutions.

2025-12-27

X-Ray Inspection of BGA Defects Video Demonstration

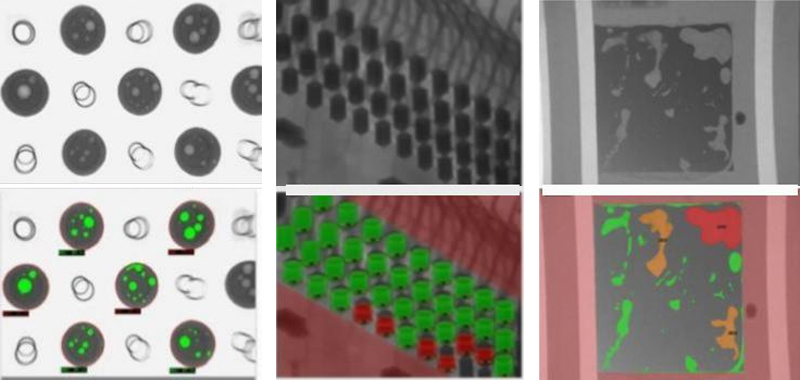

Wahfei's X-Ray inspection system is specifically designed for this purpose. The system offers real-time, off-axis X-Ray imaging, specially tailored for the inspection of PCBA (Printed Circuit Board Assembly) and array-type devices. It is suitable for use both in production lines and in failure analysis laboratories. The sample can be rotated 360° and supports large tilt viewing angles; combined with an intuitive software interface, it enables operators to clearly observe and identify even the most challenging defect types.

2025-12-24

Industrial X-Ray Inspection for SMD and FPC Assemblies with Hidden Solder Joints

For products such as SMD and FPC assemblies with complex structures and hidden solder joints,industrial X-ray inspection is no longer just a supplementary quality control method.It can be integrated as a core inspection process, enabling manufacturers to identify internal soldering defects before shipment and effectively reduce hidden quality risks.

2025-12-19

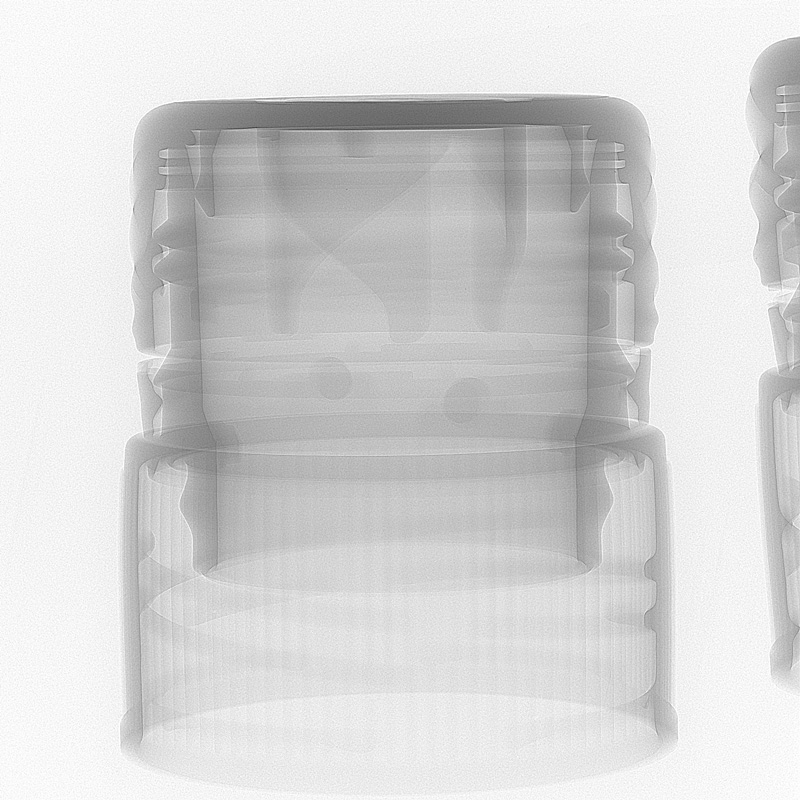

X-Ray Inspection for High-End Cosmetics like Lipsticks and Liquid Lip Tints & Plastic Packaging

Traditional inspection methods often rely on manual sampling or destructive unpacking. This is not only inefficient but also fails to cover every product leaving the factory. Especially for items with composite plastic and metal packaging, such as lipsticks and liquid lip tints, how to inspect the internal condition without opening, touching, or damaging the exterior has become an industry pain point. This is exactly where modern industrial X-ray inspection equipment comes into play. Leveraging the strong penetrative power and density resolution of X-rays, we can conduct a thorough “CT scan” of each product, examining it from the inside out.

2025-12-17

Why is industrial X-Ray computed tomography (CT) particularly well-suited for inspecting injection-molded parts?

Random sampling, prototyping, first article inspection (FAI), and mold geometry optimization each have distinct inspection objectives requiring different types of analysis. X-ray CT systems and high-quality standard X-ray solutions deliver a wide range of results.

2025-12-02

X-Ray Non-Destructive Testing for FPC Circuits

X-Ray Testing System Real-Time Imaging Interface / High-Resolution X-Ray Imaging Clearly Reveals FPC Internal Structure

2025-11-29

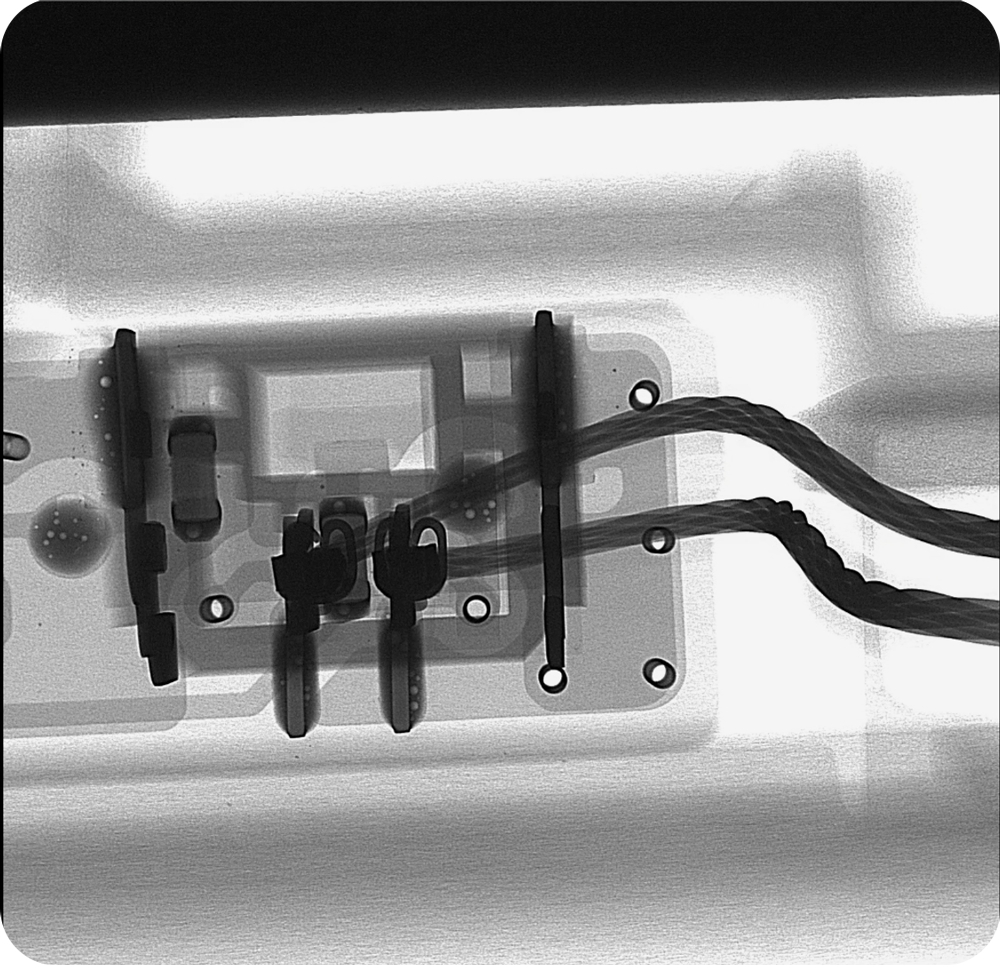

X-Ray Inspection of Injection-Molded Parts · Live Demonstration of Foreign Object Detection in Metal Power Enclosures

During the production of injection‑molded parts and metal power enclosures, foreign object contamination is often hidden and unpredictable, impacting both yield and safety. With high‑resolution imaging technology, metallic debris, plastic residue, assembly omissions, and other internal defects can be precisely located without cracking or damaging the sample structure, helping manufacturers identify risks in time and maintain stable production quality.

2025-11-17

Core Considerations for Procuring X-Ray Inspection Equipment

In the fields of electronics manufacturing, integrated circuit packaging, automotive parts, and precision casting inspection, X-Ray equipment has become a critical tool for quality control. However, many companies focus excessively on hardware parameters when purchasing equipment, while overlooking a core fact: under the same shooting conditions, image processing technology is the key factor that determines inspection results.

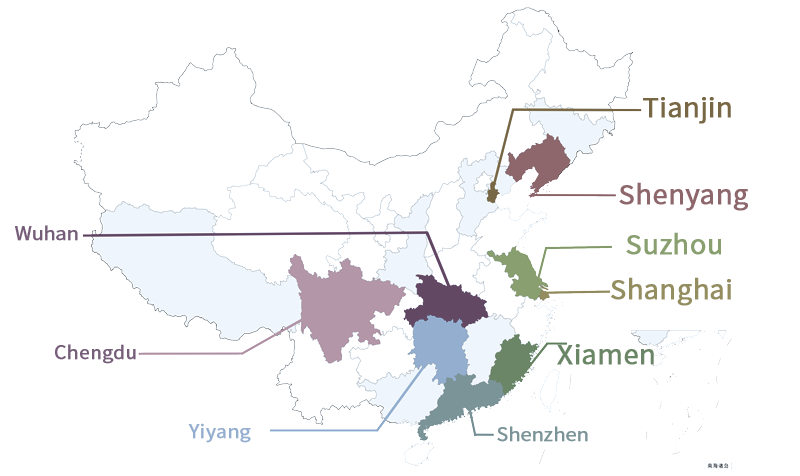

Our Offices

-

SuzhouEast China

SuzhouEast China -

DalianNortheast China

DalianNortheast China -

YiyangCentral China

YiyangCentral China -

TianjinNorth China

TianjinNorth China -

ShanghaiEast China

ShanghaiEast China -

XiamenEast China

XiamenEast China -

ShenzhenSouth China

ShenzhenSouth China -

WuhanCentral China

WuhanCentral China -

ChengduSouthwest China

ChengduSouthwest China