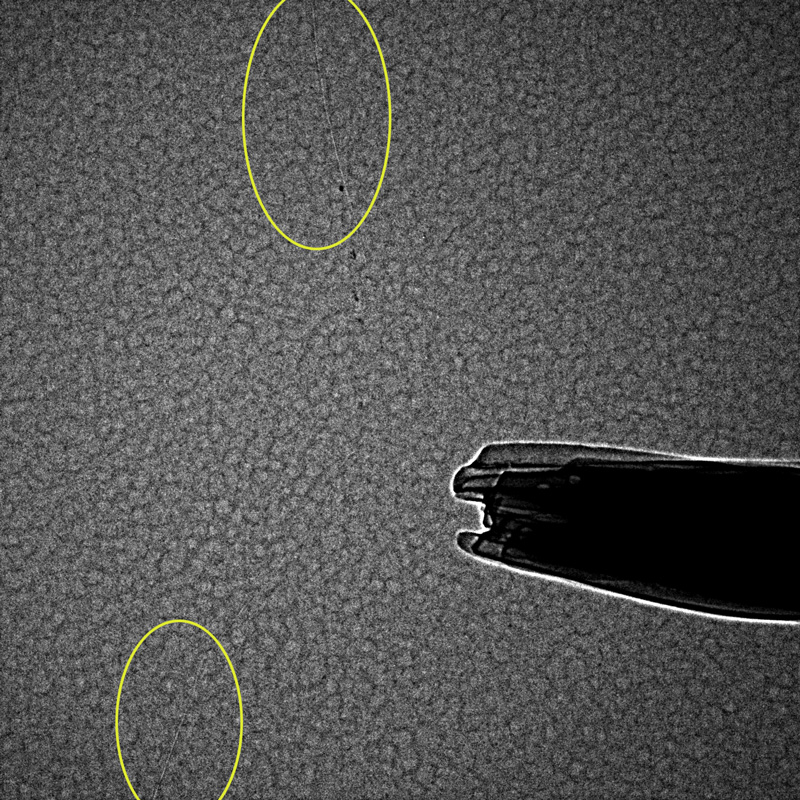

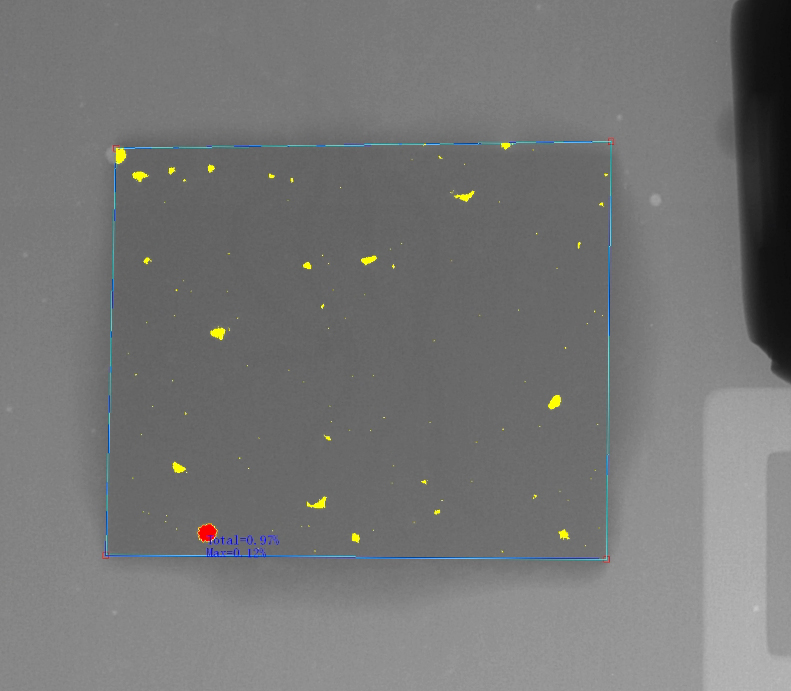

X-ray non-destructive testing of ceramic plates for micro-cracks, leaving no hidden fractures undetected.

X-ray inspection technology, with its unique penetrating capability, stands as the ideal choice for non-destructive testing of microcracks in electronic ceramic substrates. It can penetrate dense ceramic materials, revealing internal structural defects as high-resolution images, thereby exposing concealed microcracks. This serves not only as a quality control measure but also as a critical safeguard ensuring product stability under extreme operating conditions.

View More

2026-02-28

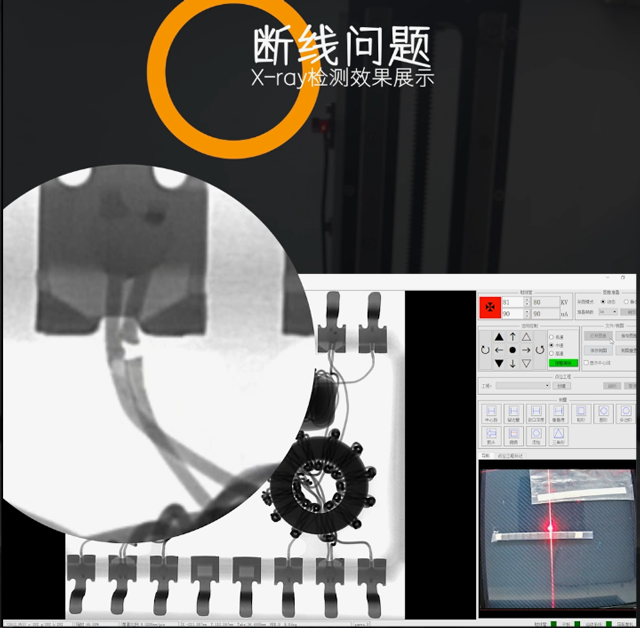

X-ray inspection for wire damage and connector breakage

For enterprises specialising in wire or connector production, the value of X-ray inspection extends far beyond merely “detecting defective products”. Its deeper significance lies in helping companies establish a quality feedback mechanism grounded in objective data. When a batch of wires consistently exhibits stress damage at identical locations, the accumulated data from X-ray images can directly pinpoint specific issues within the production process—whether it be improper pressure settings in the crimping dies or excessive bending along the routing path. This direct link from defect imagery to the root cause in the manufacturing process is something traditional inspection methods simply cannot provide.

View More

2026-02-25

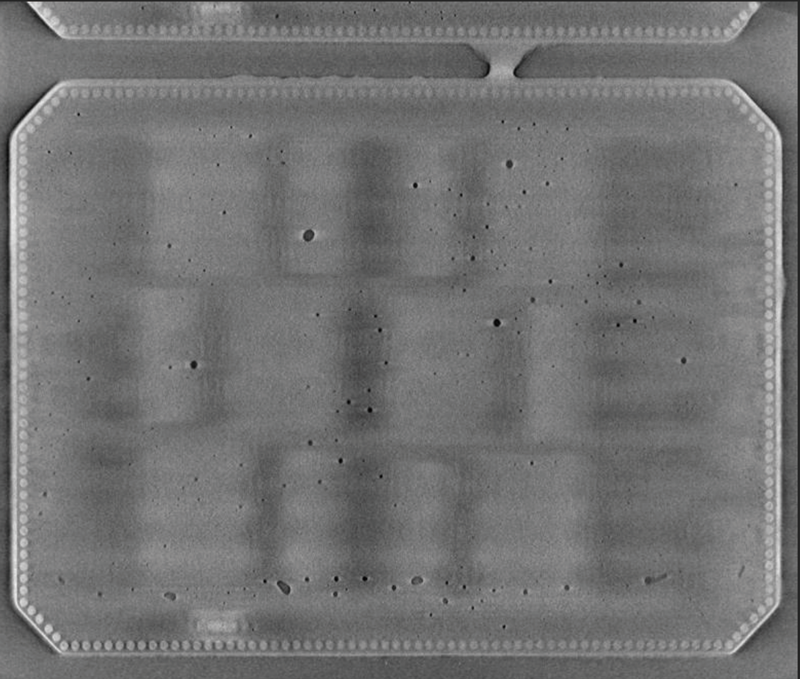

3D-CT AXI Enables Non-Destructive Testing of IGBT Power Modules

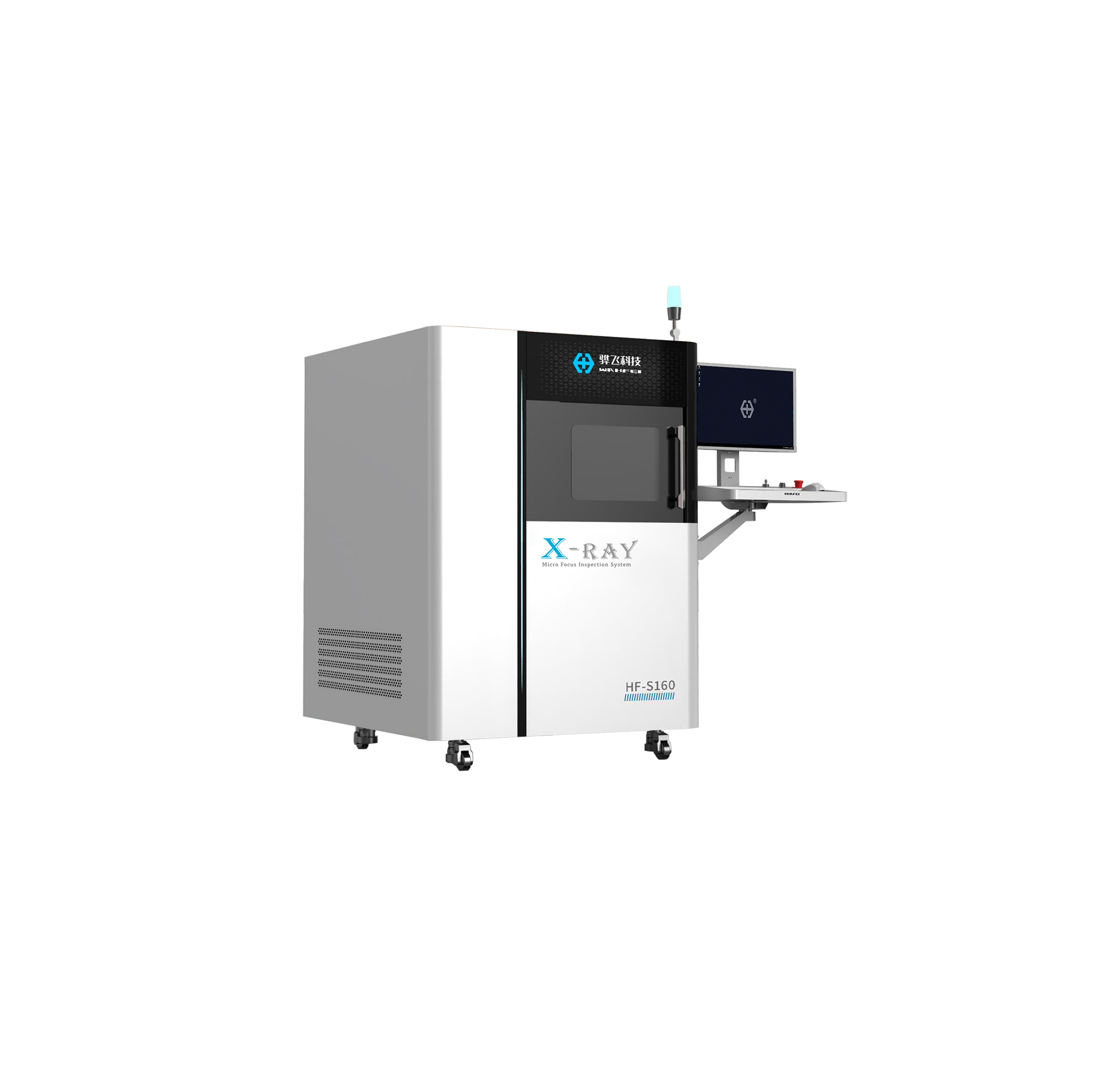

Reliability is paramount for IGBT (Insulated Gate Bipolar Transistor) power modules in the semiconductor field. Defects such as voids within the welded layer pose critical risks to performance and lifespan. To address this challenge, Huafei has introduced a 3D-CT AXI inspection system specifically engineered for IGBT power modules. This equipment achieves industry-leading inspection speeds while reliably detecting manufacturing defects that are difficult to identify using conventional methods. It also offers outstanding operational convenience and maintainability.

View More

2026-02-07

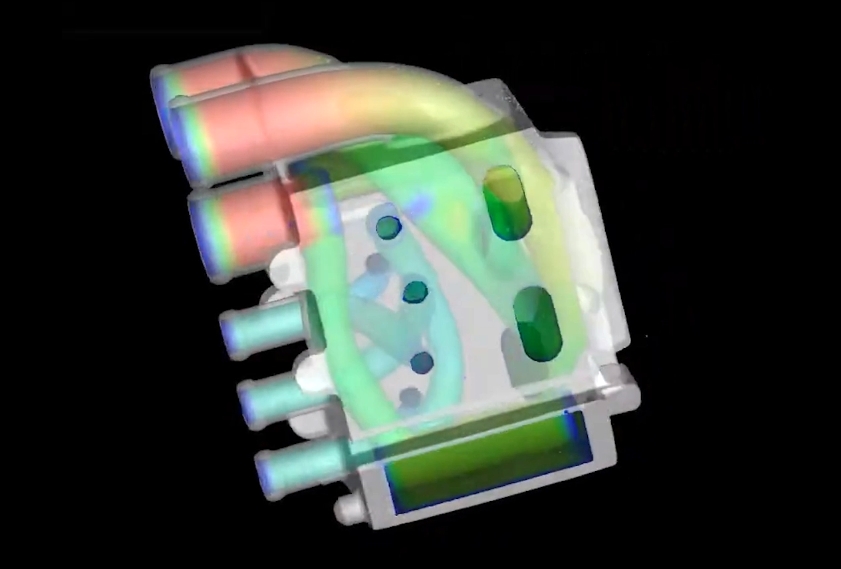

X-Ray CT Inspection: Non-Destructive Internal Defect Detection Solutions for Plug-in Units, Nozzles, Connectors, and Manifolds

Explore how X-Ray CT inspection technology provides non-destructive, high-precision internal defect detection for precision components such as plug-in units, nozzles, connectors, and manifolds, improving product quality and reliability. Learn how the Wahfei XT1000 CT inspection system addresses your inspection challenges.

View More

2026-02-06

How Open-Tube Microfocus X-Ray Inspection Technology Empowers Precision Electronics and Semiconductor Manufacturing

The open-tube microfocus X-ray, serving as the core component of precision X-ray inspection equipment, resolves this critical challenge. Its technical advantages are manifested in: ultra-high precision, high optical magnification, and high reliability. Maintainability: the open-tube design permits users to replace consumables such as filaments themselves, effectively reducing long-term operational costs. Open-tube microfocus X-ray technology, as the core component of precision X-ray inspection equipment, resolves this critical challenge. Its technical advantages are manifested in: ultra-high precision, high optical magnification, exceptional reliability, and maintainability. The open-tube design permits users to replace consumables such as filaments themselves, effectively reducing long-term operational costs.

View More

2026-01-30

PCBA X-Ray Inspection Video Demonstration

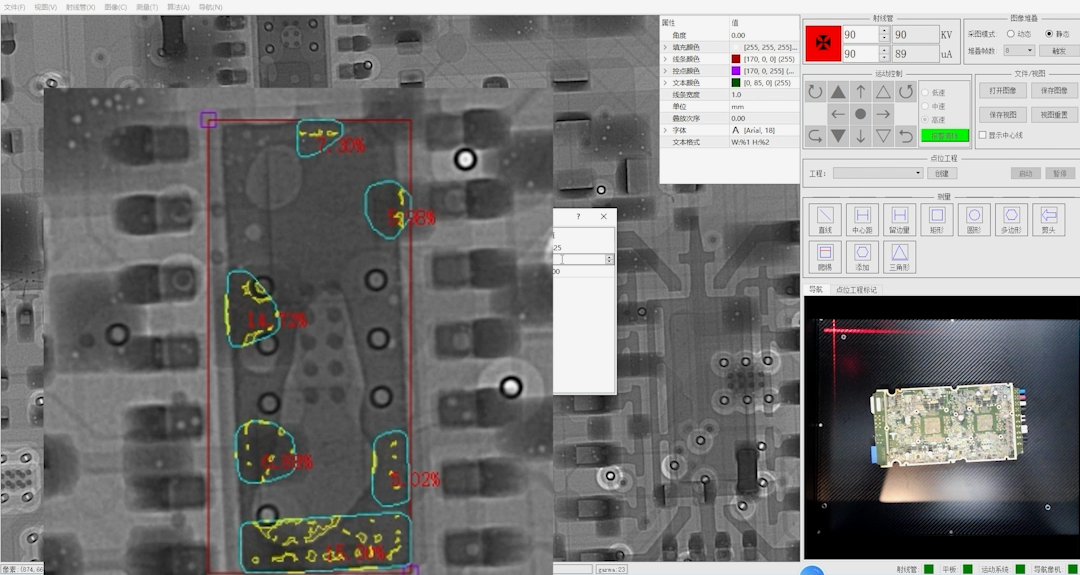

The demonstration video of PCBA X-ray inspection reveals that X-ray inspection equipment is not merely a tool for visualisation, but also a vital diagnostic apparatus that quantifies defects and integrates them into standardised processes.

View More

2026-01-29

X-Ray Inspection of Corrugated Hose Welds

As a critical flexible connector in industrial piping systems, the weld quality of bellows directly impacts the safety and reliability of the entire system. This paper will delve into how X-ray non-destructive testing technology can be utilized to accurately identify potential defects in the longitudinal welds and end joint connections of bellows.

View More

2026-01-24

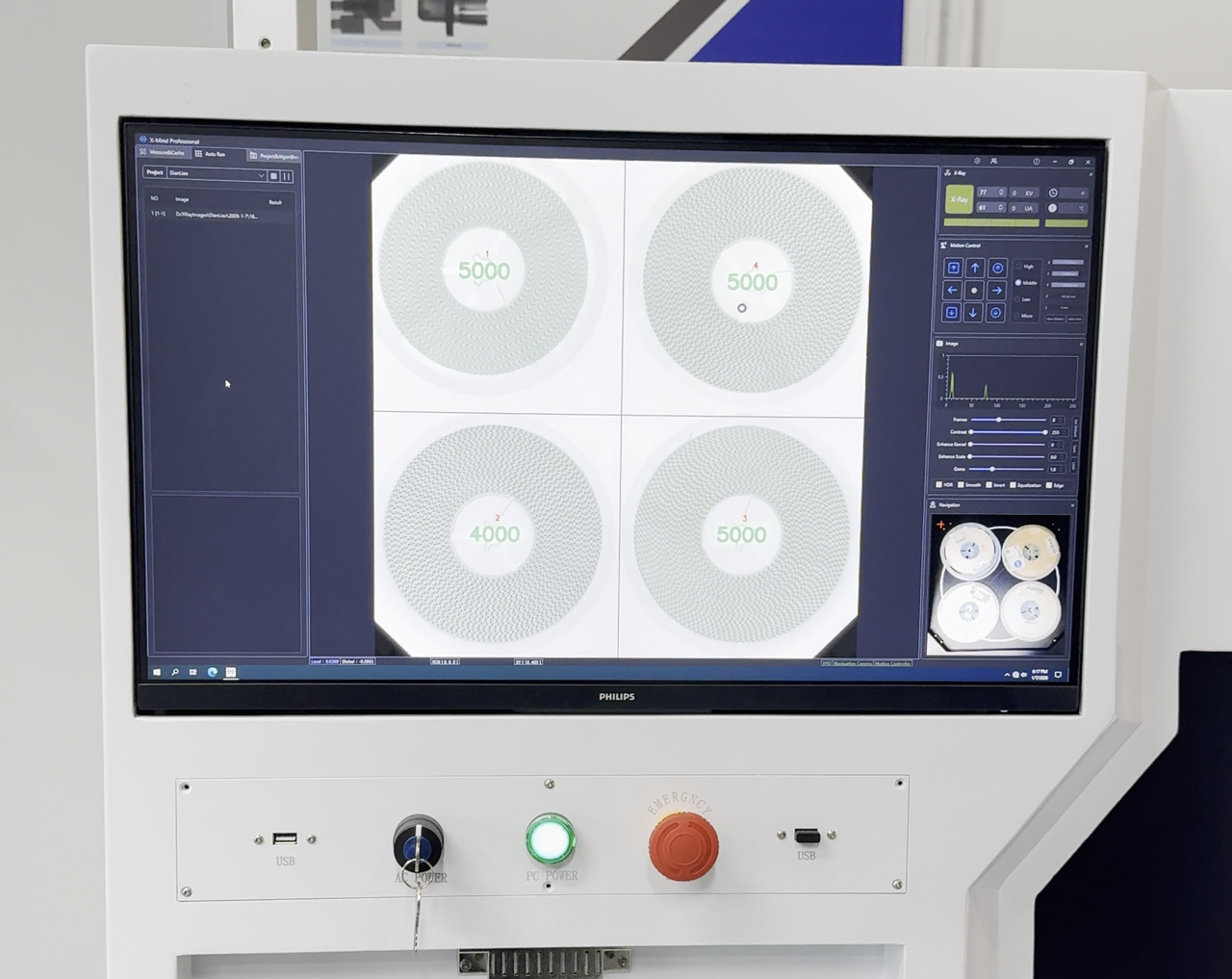

X-Ray Component Counting & Inspection Combo Machine — Official Operation Guide

In electronic manufacturing, SMT incoming inspection, and semiconductor packaging processes, X-Ray inspection equipment does more than simply “see inside structures.” It directly affects material counting accuracy, inspection efficiency, and the stability of downstream processes. To address the issues of low efficiency, high error rates, and the inability of traditional manual counting to simultaneously detect internal defects, integrated X-Ray solutions that combine material counting and inspection are increasingly becoming standard equipment for many enterprises.

View More

2026-01-23

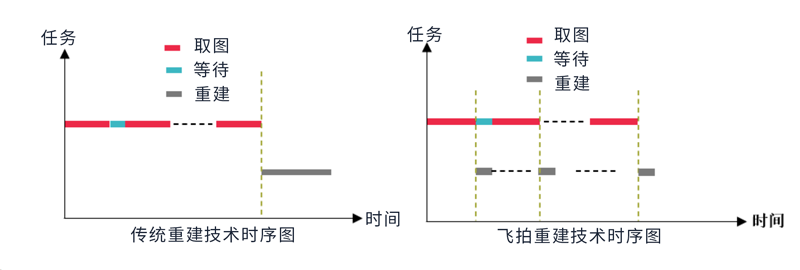

Detailed Explanation of Microfocus X-Ray CT 3D Reconstruction Technology

In the electronics manufacturing industry, the detection of internal product defects has always been a crucial part of quality control. Traditional 2D X-Ray inspection can only provide a flat projection, making it impossible to accurately locate the three-dimensional position of defects. The emergence of microfocus X-Ray CT tomography and 3D reconstruction technology has completely changed this scenario—it can reveal the internal structure of products layer by layer, much like "slicing a watermelon," exposing hidden defects such as solder voids, cracks, and foreign objects that were previously undetectable.

View More

2026-01-20

X-Ray Inspection System Applications in Various Industrial Products

Covering IGBTs / PCBA / connectors / semiconductor packages / lithium batteries / wires / LEDs / diamonds / heat pipes, etc.

View More

2026-01-17

The Mandatory Final Check: X-Ray for Zero-Defect PCBA Manufacturing

Can't inspect hidden solder joints? X-Ray inspection is your final quality gate. Learn how it visualizes BGA balls, measures voiding, and prevents costly escapes in network, security, and industrial control hardware before shipment.

View More

2026-01-16

X-Ray Automated Inspection for Internal Product Defects - Solving Inspection Challenges for BGAs, IGBTs

Simple operation allows even non-technical users to get started quickly. One-click detection identifies internal defects such as BGA solder joint failures, IGBT bubbles, and PCB solder bridges. Boost inspection efficiency with MES system integration to reduce scrap rates and labor costs.

View More

2026-01-15